Definition of Insulation Material Temperature Ratings

Temperature rating of insulation materials refers to the maximum continuous operating temperature a cable’s insulation can withstand without significant degradation. It is typically measured in degrees Celsius (°C) and standardized by organizations such as IEC, UL, and IEEE. This rating is critical for determining a cable’s suitability for specific environments and directly impacts its operational lifespan and reliability.

Chemical Changes in Insulation Materials at High Temperatures

At elevated temperatures, the molecular structure of insulation materials undergoes irreversible changes that reduce their mechanical and dielectric properties. Key degradation mechanisms include oxidation, which introduces polar groups that increase brittleness; thermal cracking, which creates microfractures due to chain scission; and cross-linking degradation, which alters polymer network stability. According to the Arrhenius law, the reaction rate of thermal degradation doubles for approximately every 10°C increase in temperature. This means that even small increments in temperature significantly shorten insulation life. The Arrhenius equation:

k = A * e^(-Ea/RT)

demonstrates how the reaction rate constant (k) increases exponentially with temperature (T), where Ea is activation energy, R is the gas constant, and A is a pre-exponential factor. This chemical instability leads to insulation breakdown, increasing the risk of failure.

Impact Comparison: Transient Overloads vs. Long-Term Overheating

Transient overloads, such as short circuits, expose cables to very high temperatures for short durations, often within seconds. In contrast, long-term overheating involves moderate temperature elevations sustained over months or years. While transient events may cause localized melting, long-term exposure results in systemic degradation. The following table illustrates the differences in impact using standard test parameters:

| Test Parameter | Transient Overload (Short Circuit) | Long-Term Overheating |

|---|---|---|

| Duration | < 1 minute | Continuous (weeks to years) |

| Temperature Rise | Up to 250°C or more | 10–30°C above rated value |

| Failure Mode | Melting, carbonization | Cracking, embrittlement |

| Key Test Standard | IEC 60949 | IEC 60216 |

| Typical Effect on Lifespan | Sudden failure | Accelerated aging |

Temperature Ratings and Failure Modes of Different Materials

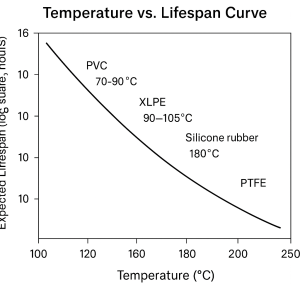

Different insulation materials exhibit distinct temperature tolerances and degradation behaviors. For example, PVC typically operates up to 70–90°C and hardens over time. XLPE withstands up to 90–105°C with excellent thermal aging resistance. Silicone rubber endures temperatures up to 180°C, offering flexibility under extreme heat. PTFE (Teflon) is the most heat-resistant, tolerating up to 250°C with minimal performance loss. The figure below shows typical temperature vs. expected lifespan relationships:

Selection Decision Tree: Choosing the Right Insulation Material

Choosing the proper insulation depends on thermal exposure, environmental stress, and electrical load. Use this basic decision tree:

- Operating Temp ≤ 90°C: PVC (Cost-effective)

- 90°C < Temp ≤ 110°C: XLPE (Better thermal aging)

- 110°C < Temp ≤ 180°C: Silicone Rubber (High flexibility)

- Temp > 180°C: PTFE (Extreme environments)

Temperature-Sensitive Scenarios and Recommendations

In sectors like renewable energy and data centers, where thermal loads vary dynamically, XLPE or silicone rubber are recommended for long-term durability and safety under elevated ambient temperatures.