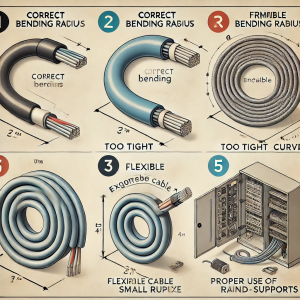

The bending radius (Bending Radius) of a cable is one of the most easily overlooked yet critically important parameters during installation. If the bending radius is too small, it may cause damage to the internal structure of the cable, affecting performance and even shortening its service life.

Understanding the Consequences of Incorrect Cable Bending Radius

To fully understand the importance of the cable bending radius, we must analyze the three main consequences that occur when this parameter is ignored or incorrectly calculated: physical damage to internal cable components, degradation of electrical performance, and a significant reduction in cable lifespan.

1. Physical Damage to the Internal Structure

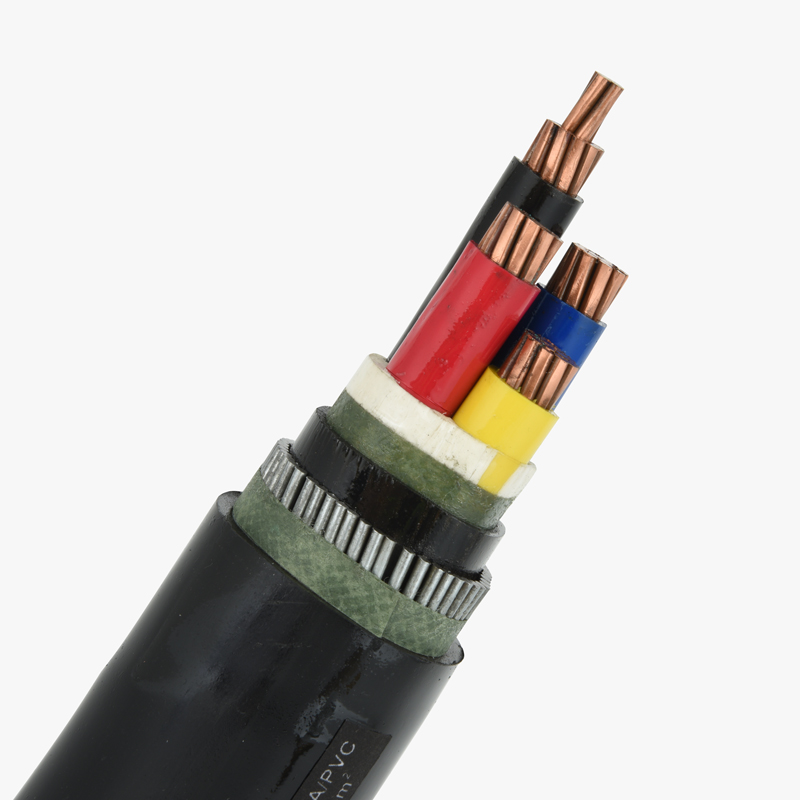

When a cable is bent beyond its minimum recommended radius, internal mechanical stress accumulates. The conductor strands may compress on the inside of the bend and stretch on the outside, leading to fractures or micro-cracking. The insulation and sheathing may also deform, crack, or delaminate. These damages are often invisible from the outside but can compromise the cable’s structure, leading to future failure. Armored cables are particularly susceptible to deformation under tight bends, which may also impair their protective qualities.

2. Impact on Electrical Performance

Cables that are bent too tightly may experience a change in conductor geometry. This distorts current pathways and increases resistance. For data and signal cables, over-bending can disrupt the shielding and pairing configuration, introducing impedance mismatches, crosstalk, or signal attenuation. In power cables, this distortion leads to voltage drop, partial discharges, and energy losses—especially in medium and high-voltage applications. When the electromagnetic field is disturbed due to poor bending practices, it directly affects performance.

3. Impact on Cable Lifespan

Even if a bent cable appears to function properly after installation, its long-term reliability is compromised. Stress caused by tight bends weakens the materials over time, leading to fatigue in the insulation and conductor. This accelerates aging, increases the chance of insulation failure, and ultimately shortens the cable’s service life. Improper installation often voids manufacturer warranties and results in higher operational costs through more frequent maintenance or replacement.

How to Correctly Calculate and Apply the Cable Bending Radius

The correct bending radius depends on the cable type and construction. As a general rule: for non-armored cables, use 10× the cable’s outer diameter (OD); for armored or shielded cables, use 15× OD. Always refer to the manufacturer’s specifications and measure from the cable centerline.

Common User Errors and Practical Solutions

Many users unintentionally damage cables by bending them incorrectly, especially during installation in narrow spaces or cable trays. Common mistakes include neglecting the manufacturer’s guidelines, estimating without calculation, and applying excessive force while pulling. These mistakes can cause immediate or latent damage, increasing project costs. The table below highlights key errors and the recommended corrective actions:

| Common Error | Solution |

|---|---|

| Bending without measuring diameter | Always calculate based on the exact outer diameter |

| Routing cables through tight corners | Use elbows, supports, or increase bend radius path |

| Assuming flexible cables can bend sharply | Follow specs—even flexible cables have limits |

| Poor cable pulling techniques | Use pulling grips and tension monitoring equipment |

| Ignoring manufacturer data | Always consult technical datasheets and installation guides |

How to Repair Cables That Have Been Overly Bent

When a cable has been bent beyond its minimum radius, the first step is to inspect it visually for outer sheath deformation or cracks. Electrical testing—such as insulation resistance or continuity testing—is critical to check for internal damage. If the results are within acceptable range and no visible damage exists, the cable may be repositioned with care. If insulation or shielding is compromised, use a certified repair kit to restore integrity. However, in high-voltage or mission-critical installations, it is safer and often necessary to replace the cable to avoid future failures. Attempting to reuse severely damaged cable sections without testing is not recommended.

Our Company’s Guidance and Assistance for Customers Installing Cables

QRUNNING offers comprehensive support to ensure our customers follow best practices during cable installation. We provide detailed technical documentation, including bending radius guidelines specific to each cable model. Our engineering team is available to consult on installation planning, offer remote or on-site supervision, and provide training to field teams. Additionally, we include printed indicators on the cable sheath and offer measurement tools to assist with accurate radius bending. Whether you’re managing a construction site or working on a power grid project, our goal is to help you install our cables efficiently and correctly the first time—ensuring long-term reliability and performance.

Case Study on the ‘Hidden Costs’ of Insufficient Bending Radius

In 2021, a regional contractor in Uzbekistan installed over 1,000 meters of medium-voltage cable for an industrial facility. Due to tight installation timelines and untrained personnel, the cables were forced through sharp conduit bends without considering minimum bending radius. Within six months, several cable segments failed under load. Diagnostic tests revealed partial discharge activity and cracked insulation at several bend points. The project incurred over $80,000 in reinstallation costs, including labor, downtime, and procurement of replacement cable. The contractor also faced penalties from the end user. This case clearly illustrates how a seemingly minor oversight in bend radius compliance can result in substantial operational and financial losses.

Summary and Customer Recommendations

Respect the minimum bending radius at all stages of installation. Always calculate it correctly, follow specifications, and seek expert support when needed. Prevention is far less costly than repair or replacement.