Core Feature Comparison: PVC vs XLPE

Choosing between PVC (Polyvinyl Chloride) and XLPE (Cross-linked Polyethylene) requires understanding their performance in key parameters. The table below summarizes critical factors to guide your decision:

| Feature | PVC | XLPE |

|---|---|---|

| Temperature Resistance | Up to 70°C (continuous) | Up to 90°C (continuous), 250°C (short-circuit) |

| Dielectric Strength | Good | Excellent |

| Short-Circuit Withstand | Moderate | High |

| Environmental Friendliness | Low (contains chlorine) | Higher (no halogens) |

| Flexibility | High (especially at low voltages) | Moderate |

| Cost | Low | Higher |

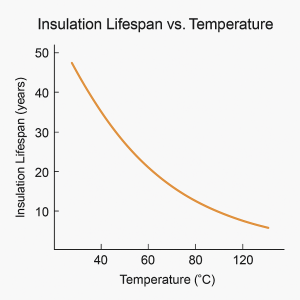

| Lifespan | 20–30 years | 40+ years |

Scenario-Based Selection Guide

PVC is ideal for indoor, low-voltage applications like conduit wiring in residential buildings, where cost-efficiency and flexibility matter most. It performs well in dry, controlled environments. On the other hand, XLPE is the preferred option for industrial power distribution, underground cabling, and areas with higher temperatures or mechanical stress. For instance, XLPE is essential in solar farms and high-load substations, where thermal endurance and longevity are critical.

Myths and Misconceptions About PVC and XLPE

Myth 1: “PVC is cheaper and more cost-effective long term” → False; XLPE’s durability reduces long-term costs.

Myth 2: “XLPE cables cannot be bent” → Incorrect; XLPE is less flexible but still manageable.

Myth 3: “PVC is more flame-retardant” → XLPE can be halogen-free and superior in fire resistance.

Myth 4: “XLPE is not eco-friendly” → In fact, it’s more environmentally friendly due to the absence of chlorine.

Myth 5: “PVC and XLPE have similar lifespans” → XLPE significantly outlasts PVC in harsh environments.

Future Trends in Cable Insulation Materials

The market is shifting toward greener alternatives to PVC, such as low-smoke, zero-halogen (LSZH) materials. Meanwhile, XLPE is evolving with nano-enhanced cross-linking technologies, improving its thermal performance and recyclability. Both materials are being refined to meet stricter international standards for safety and sustainability.

Conclusion and Customer Recommendations

For high-performance and long-term reliability, XLPE is the better choice for demanding applications. Use PVC for cost-sensitive, indoor, and less critical environments. Choose based on your project’s specific load and environmental needs.