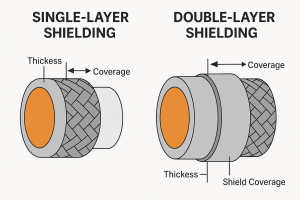

Basic Comparison of Shielding Structures

Shielded cables utilize one or more conductive layers to block electromagnetic interference (EMI). A single-layer shield generally consists of a braided mesh or foil wrap around the core conductor, providing moderate protection. Double-layer shielding combines two layers—typically a foil and a braid—to deliver superior EMI performance across wider frequency ranges. The cross-section below illustrates the structural differences, where single-layer shields typically offer 60–85% coverage, while double-layer designs provide up to 100% with overlapping materials.

Electromagnetic Interference (EMI) Suppression Capability

Electromagnetic interference can significantly affect signal integrity, particularly in high-frequency or industrial environments. Single-layer shielding is adequate for basic protection, especially against high-frequency (HF) EMI. However, it often falls short in suppressing low-frequency (LF) noise such as power line disturbances or motor interference. Double-layer shielding—combining both foil and braided components—extends protection across both LF and HF spectrums, offering comprehensive EMI suppression. This is crucial in applications like industrial control, data transmission, or aerospace systems, where uninterrupted signal transmission is vital. The dual-layer approach forms a more complete Faraday cage, minimizing radiated and conducted emissions more effectively.

Flexibility and Mechanical Properties

Single-layer braided shielded cables are more flexible due to reduced material use and simpler construction. This flexibility makes them ideal for mobile devices, robotics, or systems requiring repeated movement. In contrast, double-layer shields—while more robust—introduce added stiffness. This trade-off must be evaluated depending on application needs. In terms of mechanical properties:

| Type | Bending Radius | Tensile Strength | Flexibility |

|---|---|---|---|

| Single-Layer | 4x cable diameter | 100 N | High |

| Double-Layer | >6x cable diameter | 150 N | Moderate |

Double-layer shielding improves tensile strength and provides better abrasion resistance, but comes with reduced pliability. Thus, users must weigh protection against installation complexity and movement constraints.

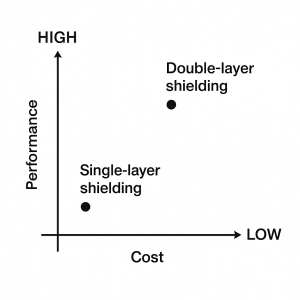

Cost and Cost-Effective Analysis

Double-layer shielding increases material cost by approximately 20–40%, depending on the configuration and metal types used (e.g., aluminum foil plus tinned copper braid). However, this added cost can be justified by the reduction in data loss, signal degradation, and system failures in high-interference environments. For cost-effective decision-making:

Selection Decision Tree

Choosing the right shielding structure depends on application, environment, and budget:

- High EMI environment? → Choose double-layer

- Low EMI, high flexibility needed? → Choose single-layer

- Budget-constrained, low-risk application? → Single-layer

- Critical signal integrity or industrial use? → Double-layer

Advice to the Client

Balance shielding performance and mechanical flexibility with your system’s needs. For high-reliability applications, double-layer shielding is worth the investment.