Are tight cable bends putting your project at risk—and your budget on the line?

When a cable is bent too sharply, copper strands can micro-fracture, insulation can craze, and shielding can deform—leading to heat buildup, signal loss, and premature failure. That means downtime, rework, and failed inspections. The fix is simple: design and install to the correct cable bend radius. As a China-based Manufacturer and Wholesaler of up to 500 kV power cable, QRUNNING offers Customisable constructions, OEM/ODM support, testable certificates, and reliable lead times from 10 production lines (200 million meters capacity). We help buyers and contractors in Vietnam and beyond get the spec—and the performance—right the first time.

The cable bend radius is the smallest curve a cable can safely form without damage. Respecting it preserves electrical integrity, eases installation, and prevents costly failures, inspections issues, and warranty claims.

Read on for clear formulas, real-world use cases, practical rules from standards like the NEC, and sourcing tips from a proven Supplier.

How To Calculate The Bending Radius Of Cable

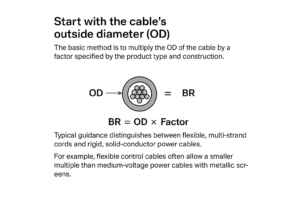

Start with the cable’s outside diameter (OD)

The basic method is to multiply the OD of the cable by a factor specified by the product type and construction. Typical guidance distinguishes between flexible, multi-strand cords and rigid, solid-conductor power cables. For example, flexible control cables often allow a smaller multiple than medium-voltage power cables with metallic screens. Always check the manufacturer’s datasheet; if a range is given (e.g., static vs. dynamic), use the stricter value during installation to avoid over-bending at pull points.

Static vs. dynamic applications

Static bend radius applies once the cable is installed and not moving; dynamic bend radius applies when the cable flexes during operation. Dynamic factors are typically larger because cyclic motion accelerates fatigue. During pulling, use generous sheave diameters and entry radii, and guide the cable so the bend occurs progressively—not at a single sharp edge.

Quick example workflow

1) Identify cable OD from the datasheet. 2) Determine the multiplier for installation and for service (static/dynamic). 3) Compute Minimum Bend Radius = OD × Multiplier. 4) Verify that tray corners, conduit sweeps, drum diameters, and termination kits all exceed this radius. 5) Document the value on your method statement so crews can measure on site with a radius template or tape.

Where are cables with a tight bend radius used?

Compact spaces that still demand reliability

Industries often push for smaller cabinets and denser routing. Robotics, machine tools, elevators, and moving gantries need cables to negotiate tight pathways while surviving constant motion. In data centers and OEM machinery, high I/O counts force small bend envelopes behind doors and in raceways. Here, selecting constructions designed for tighter bends—fine-stranded conductors, suitable insulation, optimized shielding, and robust outer jackets—keeps performance stable without resorting to oversized enclosures.

Installation realities on jobsites

In construction, bends accumulate at tray turns, risers, and entry glands. Using factory-approved accessories (sweeps, saddles, rollers) prevents kinks. For power projects in developing markets—our main export destinations—logistics sometimes dictate smaller drums or manual handling; planning the cable bend radius alongside drum size and pull route avoids field improvisation that can nick insulation and void warranties. QRUNNING provides drum and pull-plan recommendations with every major shipment to help your team maintain the correct radius from off-loading to termination.

Importance of adhering to bend radius specifications

Electrical, mechanical, and compliance consequences

Over-bending can thin insulation at the outer arc and compress it at the inner arc, shifting conductor position and increasing local electric stress—especially critical at higher voltages. Mechanically, repeated tight bends strain copper or aluminum, causing hardening and eventual conductor breakage. For instrumentation and data, deformed geometry changes impedance, elevates crosstalk, and degrades shielding, leading to intermittent faults that are costly to diagnose. From a compliance standpoint, inspections focus on workmanship: ignoring specified radius can trigger rework, schedule delays, or failed acceptance tests.

Procurement and warranty impact

Specifications often lock the minimum radius into the purchase order. If installers exceed limits, responsibility can shift between contractor and supplier. As a seasoned Supplier and Manufacturer, we embed the minimum bend radius on our datasheets and crate labels, and we can tailor Customisable constructions—strand class, screen design, or jacket compound—to meet your routing constraints without compromising lifespan. This balance protects both your budget and your project reputation.

What is the NEC code for wire bending radius?

How the NEC approaches bends

The NEC (National Electrical Code) addresses two related ideas. First, it requires adequate wire-bending space in cabinets, panelboards, and enclosures so conductors can enter and terminate without sharp deformation; these articles prescribe minimum clearances based on conductor size and equipment rating. Second, for cables and conductors, the NEC expects installers to follow the manufacturer’s specified minimum bend radius and any equipment listing or product standard that applies (for example, for medium-voltage accessories or tray systems). In practice, that means: size your enclosures per NEC tables, select fittings compatible with your conductor sizes, and never force a cable below the radius printed or published by the maker.

Practical takeaways for contractors and buyers

During design, verify that your chosen conduit sweeps, cable tray turns, and termination kits exceed the required bend radius. During installation, use rollers or sheaves of adequate diameter and protect edges with radius saddles. For inspection, keep datasheets on hand to show the authority having jurisdiction that your bends meet both the NEC’s space rules and the product’s bend-radius specification. QRUNNING can provide compliance letters and test data on request to streamline approvals.

Sourcing cables that meet bend radius demands

Why QRUNNING fits projects in Vietnam and beyond

As a B2B Wholesaler and Manufacturer with 30+ years of experience, we supply up to 500 kV power cable with audited quality control, authentic certification, and reliable ETD/ETA. Our factory’s 10 lines support large orders with stable lead times, and our engineering team helps you balance bend radius, ampacity, and budget. Need a tighter route? Ask about Customisable strand classes, armor options, and jacket materials that achieve your target cable bend radius without sacrificing life expectancy.

Summary

Respect the cable bend radius to protect performance, pass inspections, and avoid downtime. Choose designs suited to your routing, follow the NEC and manufacturer limits, and partner with a proven Supplier for dependable results.