Are you struggling to choose the right construction cables that balance quality, cost, and long-term reliability? Many project owners and contractors face delays, safety risks, and budget overruns because of poor cable selection. Low-grade materials, unclear standards, and unreliable Suppliers often lead to frequent replacements and hidden maintenance costs. The solution lies in selecting high-standard cables from a proven Manufacturer. As a Chinese leading cable Wholesaler with over 30 years of experience, QRUNNING provides construction cables up to 500kV, strict quality control, verified certifications, and Customizable OEM&ODM services to ensure safety, longevity, and cost efficiency.

Choosing high-standard construction cables from a reliable Manufacturer reduces installation risks, controls fiber optic installation costs, and extends service life. Partnering with an experienced Wholesaler and Supplier ensures compliant, durable, and customizable solutions for modern building projects.

Understanding cable quality, installation costs, and lifespan is essential for making smarter decisions. Let’s explore how to optimize your cable selection for long-term construction success.

High-Standard Cable Products for the Construction Industry

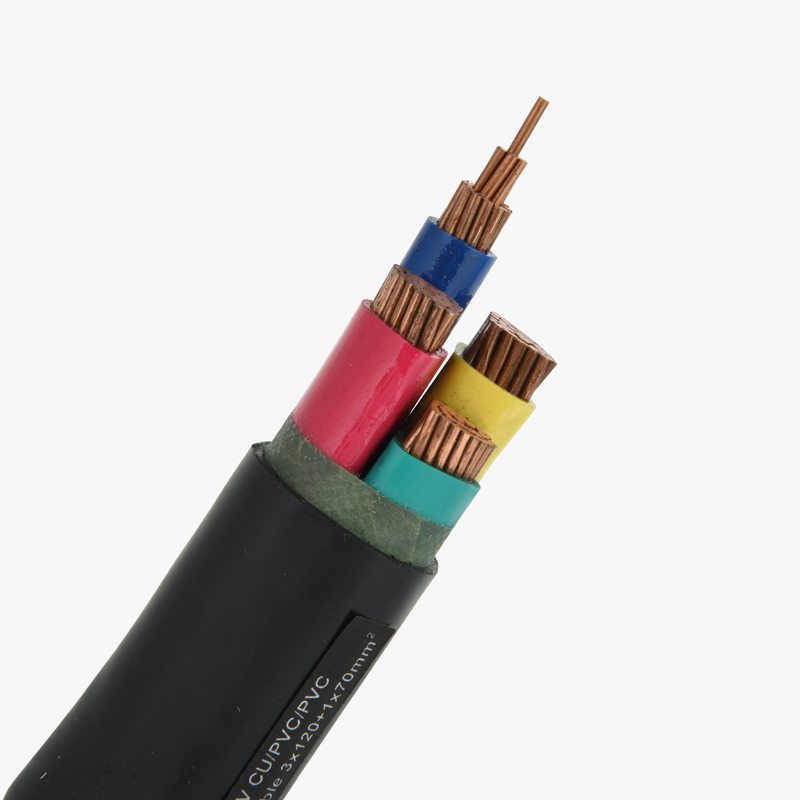

High-standard cables are the foundation of safe and efficient building projects. In the construction industry, construction cables must meet strict electrical, mechanical, and environmental requirements. This includes resistance to heat, moisture, corrosion, and mechanical stress during installation and long-term operation. Selecting products from a qualified Manufacturer ensures compliance with international standards and reduces the risk of failure.

Why Quality Standards Matter

Substandard cables may appear cost-effective initially, but they often result in overheating, signal loss, or insulation breakdown. These issues can disrupt power distribution and communication systems, especially in large commercial or infrastructure projects. High-standard cables are engineered with premium conductors, advanced insulation, and precise manufacturing processes, making them ideal for demanding construction environments.

Role of a Reliable Supplier

A professional Supplier or Wholesaler provides not only products but also technical guidance. Experienced suppliers offer Customizable solutions tailored to project voltage levels, installation conditions, and regulatory requirements. This approach improves overall project efficiency and ensures long-term operational stability.

What Is the Cost per Foot for Laying Fiber Optic Cables?

The cost per foot for laying fiber optic cables varies depending on several factors, including cable type, installation method, labor, and site conditions. On average, fiber optic installation costs are influenced more by labor and civil works than by the cable itself. Trenching, conduit installation, and termination can significantly affect the final budget.

Key Cost Factors

Indoor installations in building projects are generally less expensive than outdoor or underground installations. However, using low-quality fiber cables may increase future maintenance costs. Choosing high-standard cables from a reputable Manufacturer helps reduce signal loss and replacement frequency, offering better long-term value.

Optimizing Costs Through Smart Cable Selection

Working with a direct Wholesaler or factory-level Supplier allows buyers to access competitive pricing and Customizable specifications. Proper cable selection ensures compatibility with building design, minimizes waste, and controls overall fiber optic installation costs without compromising performance.

What Is the Service Life of Power Cables?

The service life of power cables is a critical consideration in construction planning. Typically, high-quality power cables can last 20 to 40 years or more when properly selected and installed. Factors such as material quality, operating voltage, environmental exposure, and load conditions directly impact longevity.

How Quality Extends Cable Lifespan

High-standard cables use superior insulation materials and conductors that resist aging, thermal stress, and chemical exposure. This is especially important for large-scale building projects where cable replacement is costly and disruptive. Selecting cables from an experienced Manufacturer ensures consistent performance throughout their service life.

Long-Term Value for Construction Projects

From a lifecycle cost perspective, investing in durable construction cables reduces downtime and maintenance expenses. A trusted Supplier offering Customizable solutions can match cable designs to specific building requirements, maximizing safety and operational efficiency over decades.

উপসংহার

Smart cable selection combines quality, cost control, and durability. By sourcing high-standard construction cables from a reliable Manufacturer and Wholesaler, building projects achieve safer operations, optimized installation costs, and long-term reliability.