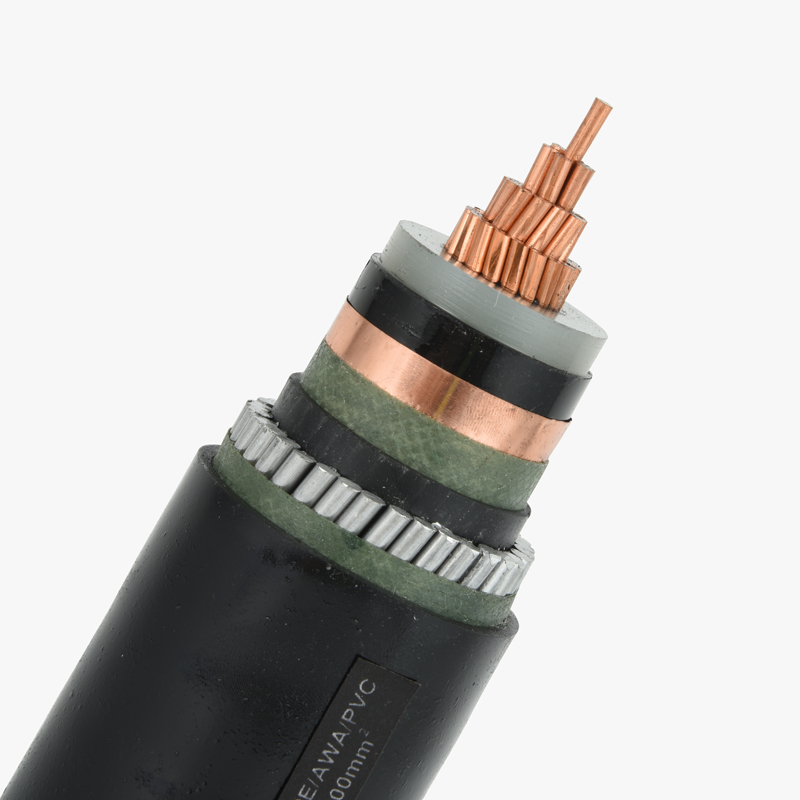

STA vs SWA Armored Cables: Structural Differences Illustrated

When comparing steel tape armour (STA) and steel wire armour (SWA) cables, the structural distinctions are clear and decisive. STA cables feature multiple layers (typically two to three) of helically wrapped steel tape over their bedding, providing flat, contiguous protection. Tape thickness ranges from around 0.4 mm to 0.6 mm, depending on voltage rating and mechanical demands. In contrast, SWA cables incorporate steel wires — often single-layer or double-layer — spiral-wound around the bedding. These wires typically range from 1.0 mm to 2.5 mm in diameter and are separated by bedding yarns, forming discrete round armour elements. The result: STA has lower radial thickness but very consistent coverage, while SWA provides higher impact resistance and flexibility for certain applications.

Definitions of STA and SWA Cables According to Standards

Steel Tape Armour (STA) cables are defined in IEC 60502‑1, featuring helically wrapped steel tape as mechanical protection; Steel Wire Armour (SWA) cables per IEC 60502‑1 use wound steel wires around the bedding. These standards specify armour levels, dimensions, tests for mechanical performance, bending radii, and earth continuity requirements.

STA and SWA Comparison Reference Table

Below is a quick comparison to help visualize the key differences between STA and SWA from structure, performance, and application perspectives.

| Feature | STA (Steel Tape Armour) | SWA (Steel Wire Armour) |

|---|---|---|

| Armour Type | Helically wrapped steel tape | Spiral steel wires |

| Typical Thickness / Diameter | 0.4–0.6 mm | 1.0–2.5 mm |

| Coverage Uniformity | High, continuous | Moderate, discrete gaps |

| Radial Thickness | Lower | Higher |

| Flexibility | Stiffer | More flexible |

Which is more pressure-resistant, STA or SWA?

Pressure and impact resistance are critical in many industrial installations. Laboratory tests indicate that SWA cables typically outperform STA in radial compression. For example, standard SWA (1.6 mm wire) withstands pressures up to 6000 N (and sometimes higher in double‑wire formats), while STA cables might resist around 3000–4000 N under the same test conditions. Tensile strength also favors SWA; its steel wires allow full-load tensile testing of 1000–2000 N without damaging the conductors. By contrast, STA’s thinner tape offers only about 400–800 N in similar tension tests before yielding. In summary, SWA is superior under high radial and tensile stresses.

Which armored cable is more suitable for complex wiring?

Complex wiring environments — such as cable trays, junction boxes, and conduits — demand flexibility and bendability. SWA, with its round steel wires and discrete spiral winding, offers a reduced bending radius and greater flexibility. It can be routed around obstacles more easily, requiring fewer cable joints. STA’s flat tape design makes it stiffer, increasing the chance of kinking if bent too tightly, and it requires a larger bending radius. Overall, for tight routing or intricate cable paths, SWA is the practical choice.

Should STA or SWA be chosen for humid environments?

Humidity and moisture exposure raise concerns about corrosion, electrical safety, and earth continuity. STA’s continuous tape provides better initial moisture sealing, especially when tape edges are overlapped tightly. However, once penetrated or scratched, corrosion can spread beneath the tape. SWA, with discrete wires, allows moisture to accumulate between wires unless bedding and sheaths are well-sealed. To offset this, many SWA cables use additional magnesium oxide powder or polymer termite-resistant fillers. Proper sheath selection (e.g., PVC with corrosion inhibitors) and sealing practices (e.g., sealed gland fittings) are more critical than armour type. In highly humid environments like tropical climates, well-sealed SWA or STA cables with corrosion‑resistant sheaths perform equally when installed correctly.

Selection decision tree: 5 questions to help you determine STA or SWA

- Does the installation require high tensile strength? — Choose SWA for pull‑in or overhead runs; STA may suffice for stationary installs.

- Are bending/flexibility needed? — Use SWA for tight routing or compact installations.

- Are budget constraints tight? — STA is generally less expensive in materials and installation time.

- Is the environment humid or corrosive? — Either is fine if proper sheaths/glands are used; sealing is key.

- Does it need earth continuity with minimal resistance? — STA’s continuous tape may offer slightly lower earth loop impedance; choose SWA if tensile requirements override.

What is the difference between HVAC and HVDC?

Although related to cable selection, the difference between HVAC (High Voltage Alternating Current) and HVDC (High Voltage Direct Current) lies in voltage type and insulation requirements rather than armour type. HVAC uses alternating current—common in power distribution—typically with concentric conductor structures and needs armour sized for thermal and dynamic forces. HVDC requires DC voltage control; its cables have insulation systems optimized for continuous DC stress, and its armour must address thermal expansion and electrochemical stability. Armour selections (STA or SWA) apply similarly to both, but insulation and conductor design criteria change.

Summary

Choose SWA for mechanical demands; STA for cost savings and simplicity.