Are cable failures, delays, and hidden costs disrupting your projects?

Many Wholesalers, contractors, and engineering buyers struggle with inconsistent cable management and unreliable sourcing. Poor manufacturer selection, unclear specifications, and weak quality control often lead to overheating, compliance risks, and costly rework. These problems escalate when suppliers lack certification transparency or production capacity. The solution starts with choosing a proven cable manufacturer and applying structured cable management practices. With over 30 years of industry experience, QRUNNING is a Chinese leading Nhà sản xuất of up to 500kV power cables, operating 10 production lines and delivering OEM & ODM, Customizable solutions for global B2B projects—ensuring quality, scale, and on-time delivery.

Cable selection and cable management depend on choosing a certified, high-capacity Nhà cung cấp and applying clear installation, routing, and labeling standards. Reliable manufacturers reduce risk, improve efficiency, and support long-term system safety—especially for large-scale power and construction projects.

Understanding the principles behind cable sourcing and organization helps you avoid common pitfalls and build safer, more efficient electrical systems from the ground up.

How to select the right cable manufacturer?

Selecting the right cable manufacturer is a strategic decision that directly impacts project safety, cost control, and delivery timelines. Start by verifying certifications such as ISO, IEC, or regional standards required for power grid and construction projects. A credible Nhà sản xuất should provide authentic test reports, transparent quality control processes, and traceable raw materials. Production capacity is equally important—insufficient capacity often leads to shipment delays and inconsistent quality.

Experienced buyers also evaluate export history and industry reputation. A global Nhà cung cấp with long-term partnerships in Africa and Asia demonstrates adaptability to different technical and regulatory environments. QRUNNING, for example, supports large-volume wholesale orders with stable lead times and offers Customizable cable designs for bidding projects and factory applications. Choosing such a partner minimizes risk and supports scalable growth.

How to achieve better cable management?

Effective cable management begins at the design stage. Clear planning of cable routes, load calculations, and separation of power and control cables reduces interference and heat buildup. Using standardized trays, conduits, and fixing methods improves safety and simplifies future maintenance. Proper labeling and documentation are often overlooked, yet they significantly reduce troubleshooting time and operational downtime.

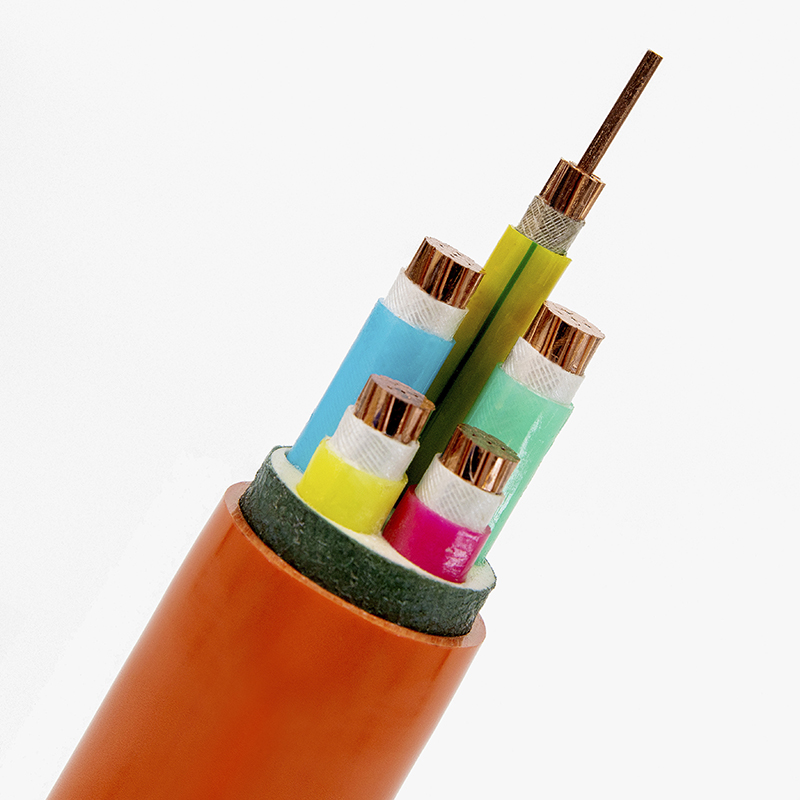

Material quality also plays a role. High-grade insulation, accurate conductor sizing, and compliant sheath materials from a reliable cable manufacturer ensure cables perform as expected under mechanical and environmental stress. Working with a professional Nhà cung cấp allows buyers to request Customizable lengths, colors, and packaging, further enhancing installation efficiency. Good management is not only about neatness—it is about long-term system reliability.

How is your cable management situation?

Many companies only assess their cable management after problems appear—overheating, signal loss, or unexpected failures. Ask yourself whether your current cables are clearly identified, properly routed, and sourced from a dependable Nhà sản xuất. If documentation is incomplete or replacement parts are hard to match, operational risk increases.

Regular audits and supplier reviews help identify weaknesses early. Partnering with an experienced Nhà phân phối or Nhà cung cấp that understands both manufacturing and application scenarios enables continuous improvement. With professional guidance and consistent product quality, your cable system can evolve from a hidden risk into a competitive advantage.

In summary, choosing the right cable manufacturer and applying disciplined cable management practices reduces risk, controls costs, and ensures long-term electrical system performance for B2B projects.