How Can You Avoid Costly Failures by Choosing the Wrong PV Wire?

Are you a Nhà phân phối, EPC contractor, or solar project buyer worried about system failures caused by incorrect PV wire selection? Many photovoltaic projects suffer from overheating, insulation cracking, or early aging because buyers focus only on price while ignoring standards, materials, and environmental conditions. These mistakes can lead to power loss, safety hazards, and costly downtime. The solution is selecting certified, application-matched photovoltaic cable products from a reliable Nhà sản xuất. With over 30 years of cable industry experience, QRUNNING provides TÜV-approved, IEC-compliant, and Customizable solar cable solutions designed for long-term reliability, stable performance, and diverse climate conditions.

Choosing the right PV wire requires compliance with IEC and TÜV standards, suitable conductor materials, wide temperature tolerance, and accurate matching to photovoltaic system conditions to ensure safety, efficiency, and long service life.

Understanding the technical differences behind PV wire options will help you make informed decisions and protect your photovoltaic investment.

Key Standards for PV Wires: IEC 60228 and TÜV Certifications

Why Standards Matter in Photovoltaic Systems

International standards play a critical role in ensuring the safety and performance of every PV wire used in solar installations. IEC 60228 defines conductor classes, resistance limits, and structural requirements, ensuring consistent electrical conductivity and mechanical flexibility. Meanwhile, TÜV certification verifies that photovoltaic cable products meet strict safety, aging, and environmental resistance tests.

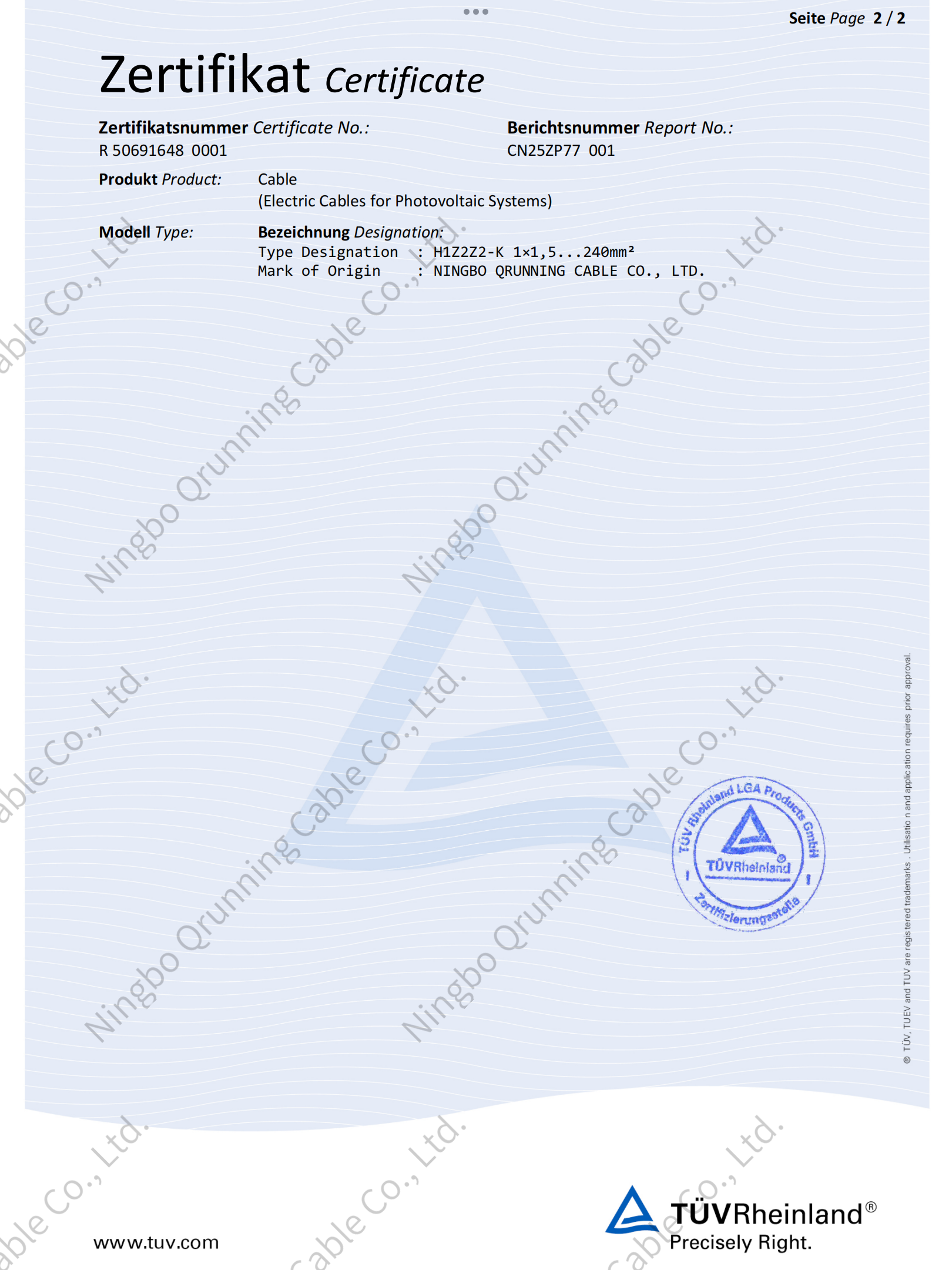

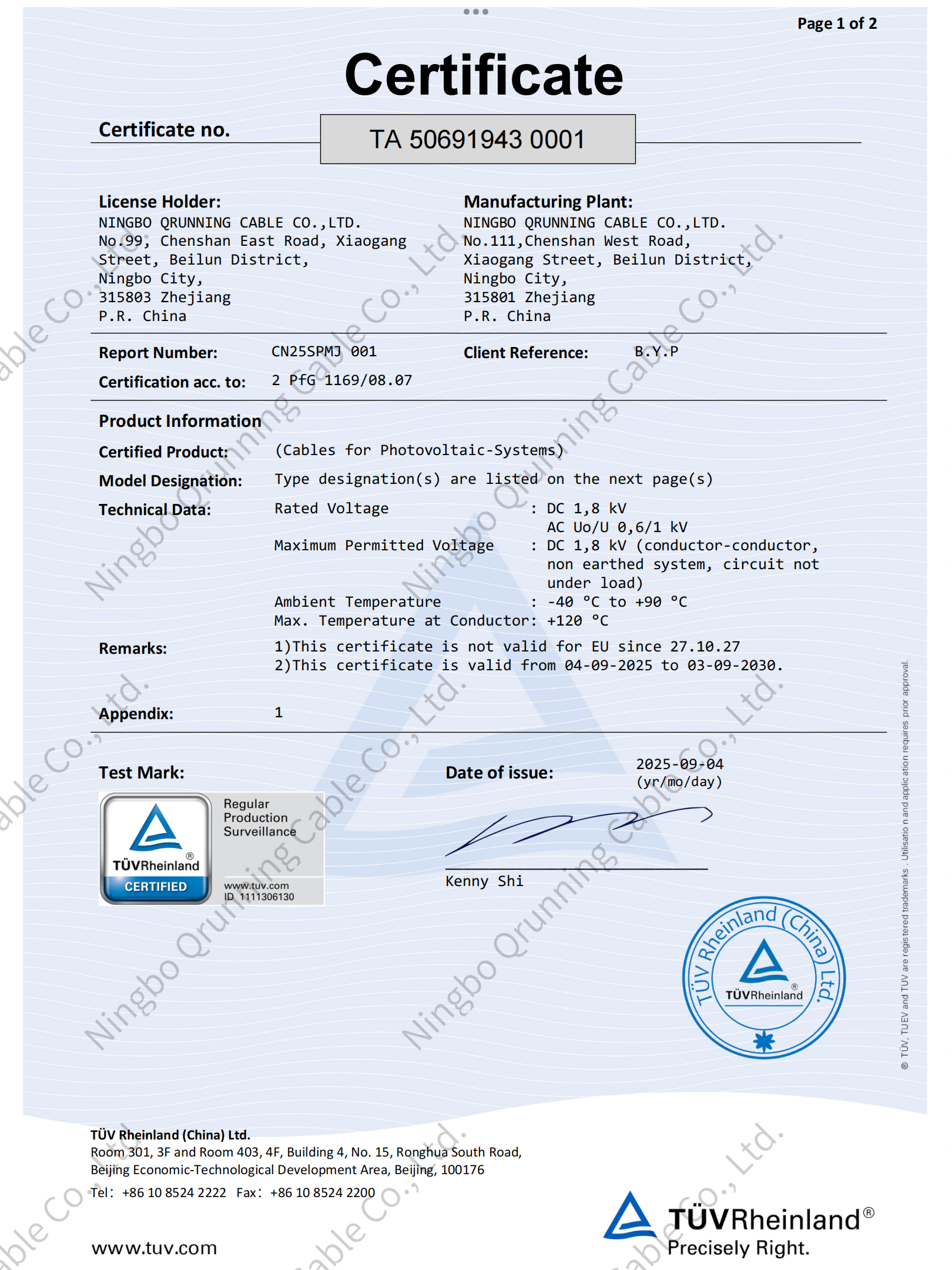

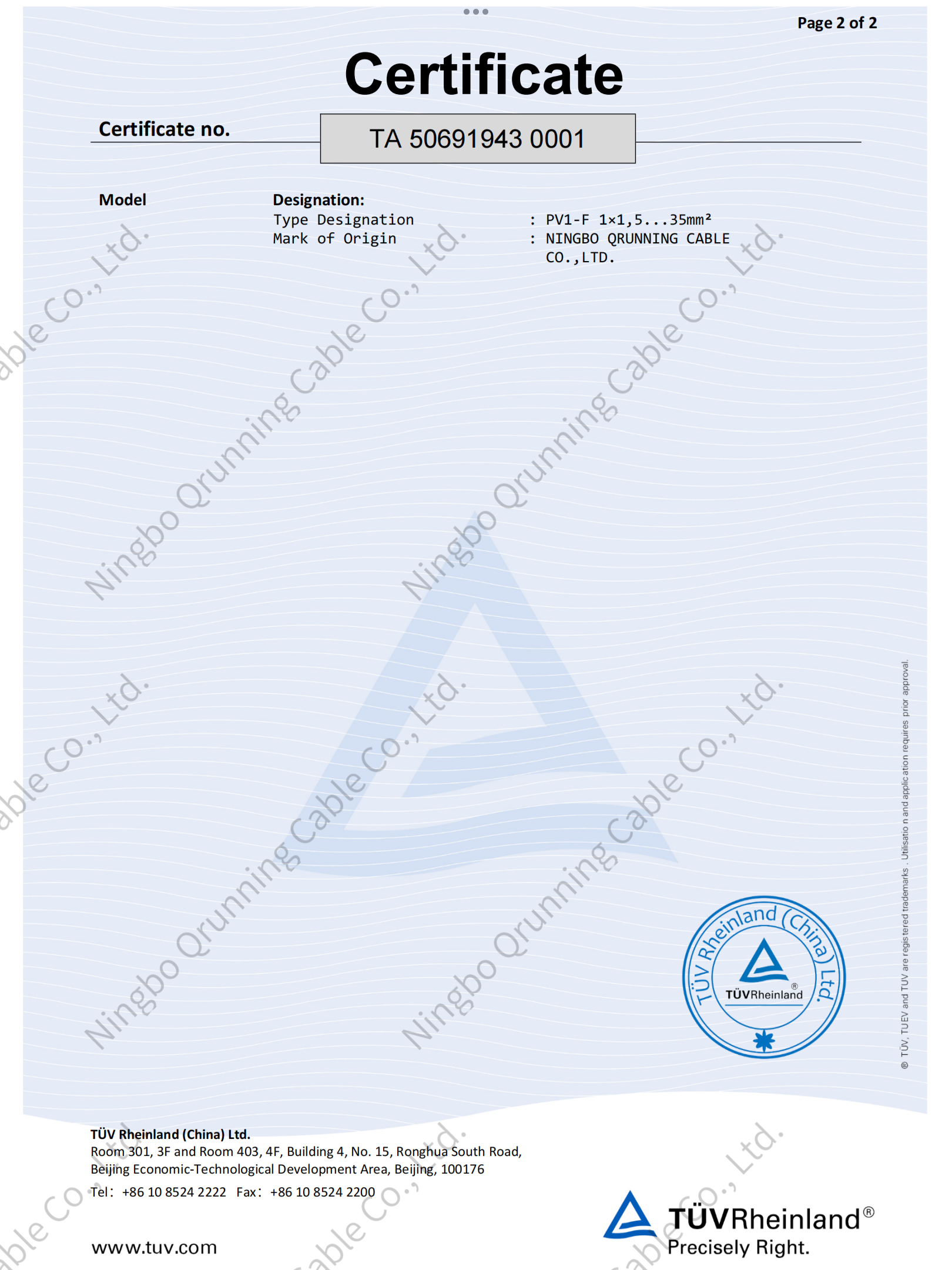

Common industry-recognized products such as PV1-F cable và H1Z2Z2-K cable are designed to comply with these standards. Working with a trusted Nhà cung cấp và Nhà sản xuất ensures authentic certification, preventing risks caused by falsified or incomplete compliance documents.

These are our TÜV certifications(PV1-F cable và H1Z2Z2-K cable):

Certification as a Risk Control Tool

For utility-scale and commercial projects, certified solar cable products simplify approval processes and improve system bankability. Wholesalers and contractors benefit from consistent quality, predictable performance, and reduced maintenance risks when standardized cables are used across projects.

Conductor Material: Copper vs. Aluminum for PV Applications

Copper Conductors in PV Wire

Copper remains the most widely used conductor material in PV wire due to its excellent electrical conductivity, flexibility, and corrosion resistance. Copper-based photovoltaic cable supports lower resistance losses and stable current transmission, making it ideal for rooftop and high-efficiency solar systems.

In addition, copper conductors perform well under frequent thermal cycling, which is common in solar applications. Leading Manufacturers often offer Customizable copper conductor designs to match voltage levels, installation methods, and local regulations.

Aluminum Conductors: Cost and Weight Advantages

Aluminum conductors offer advantages in large-scale solar farms where weight reduction and cost control are priorities. While aluminum has higher resistance than copper, modern conductor designs and proper sizing help mitigate efficiency loss.

Choosing aluminum-based PV wire requires careful consideration of termination methods and anti-oxidation treatments. An experienced Nhà cung cấp can provide technical guidance to ensure safe and compliant aluminum conductor applications.

Temperature Range: Adapting to Extreme Climates

Thermal Performance of PV Wires

Photovoltaic installations often operate in extreme environments, including deserts, coastal areas, and high-altitude regions. A high-quality PV wire must withstand wide temperature ranges without cracking, softening, or losing insulation integrity. Products like H1Z2Z2-K cable are designed to perform reliably from sub-zero temperatures to extreme heat.

Advanced insulation materials and cross-linked compounds allow solar cable products to resist UV radiation, ozone, and moisture. Selecting a Nhà sản xuất with proven material expertise ensures consistent performance throughout the system lifecycle.

Climate-Specific Customization

Customizable temperature ratings and insulation thickness help adapt photovoltaic cable designs to local climate challenges. This flexibility is especially valuable for international Wholesalers supplying diverse markets.

Understanding PV System Requirements and Operating Conditions

Matching Cable to System Design

Every photovoltaic system has unique electrical and mechanical requirements. Voltage rating, current capacity, installation method, and exposure conditions all influence the selection of the correct PV wire. Using undersized or mismatched solar cable can lead to overheating, voltage drop, and reduced system efficiency.

Professional Suppliers evaluate system layouts and recommend appropriate PV1-F cable or H1Z2Z2-K cable solutions. This approach ensures that each photovoltaic cable operates within safe limits, maximizing energy yield and system reliability.

Long-Term Reliability and Maintenance

Considering operating conditions such as vibration, chemical exposure, and mechanical stress is essential for long-term performance. High-quality materials, certified production processes, and strict quality control from a reputable Nhà sản xuất reduce failure risks and maintenance costs.

Kết luận

Selecting the right PV wire means prioritizing certified standards, suitable conductor materials, climate adaptability, and system compatibility, all supported by a reliable Nhà cung cấp and experienced Nhà sản xuất.