Are your projects losing bids because you don’t fully trust the performance of MICC Cables?

Problem: Many buyers — contractors, project managers, and electrical distributors — worry that Mineral Insulated Cables will fail under harsh conditions, cost too much, or arrive late, which can sink bids and delay construction. Agitation: that uncertainty leads to conservative sourcing, missed opportunities, and costly rework when low-quality cables or fake certificates appear. Solution: partner with a reliable Manufacturer and Supplier. At QRUNNING we offer **MICC Cables** backed by 30+ years of production experience, OEM/ODM Customizable options, strict quality control, and large factory capacity to ensure on-time shipments for wholesalers and major contractors.

Mineral Insulated Cables (MICC) are copper conductors inside a compacted magnesium oxide core and metal sheath, delivering fireproof, high-temperature, and long-life performance for critical power and instrumentation circuits.

Curious how MICC Cables can change your project risk profile? Read on — this guide breaks down uses, limitations, and lifespan in plain language.

What is a mineral insulated cable?

Construction and materials

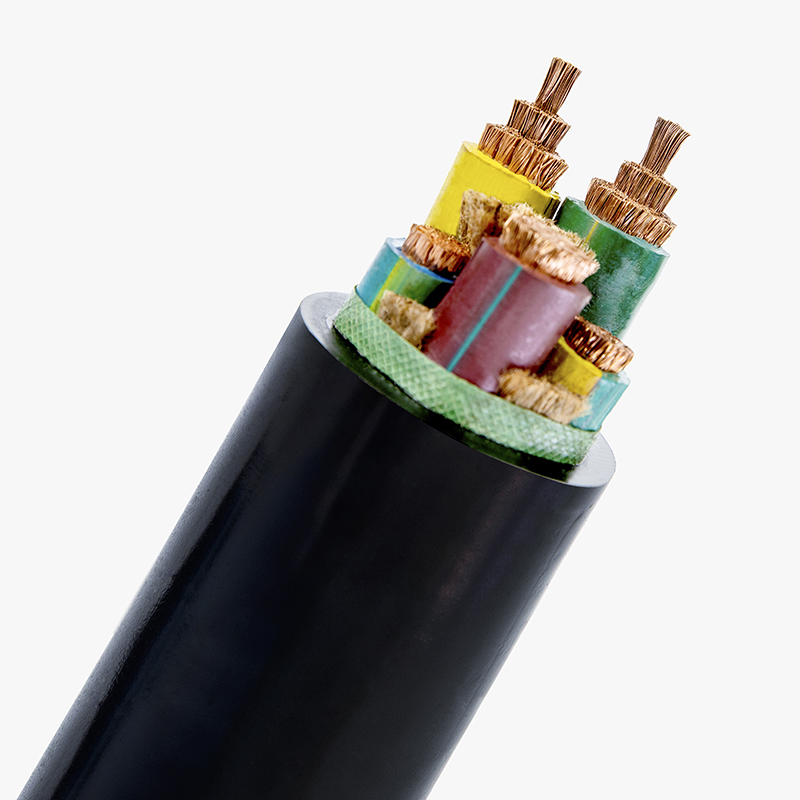

Mineral Insulated Cables (often called MICC Cables) consist of one or more solid copper conductors embedded in a highly compacted magnesium oxide (MgO) powder, all enclosed within a seamless metal sheath (typically copper, stainless steel, or aluminum). The MgO provides excellent electrical insulation and thermal conductivity while being non-combustible. The metal sheath protects the core from moisture, mechanical damage, and corrosive environments.

Why this structure matters

Because the insulating material is a mineral rather than plastic, MICC Cables maintain integrity at very high temperatures, resist flame spread, and do not emit toxic smoke like many polymer-insulated cables. For buyers — whether a Wholesaler, large engineering firm, or procurement manager — that means predictable performance in safety-critical systems.

What is MICC cable used for?

Typical applications

**MICC Cables** are widely used where fire integrity and long-term reliability are non-negotiable. Common applications include fire alarm systems, emergency lighting, smoke control, power distribution in high-rise buildings, oil & gas installations, power plants, and tunnel infrastructure. Their immunity to heat and flame makes them preferred for life-safety circuits and essential communications.

Industry sectors and customers

As a Manufacturer and Supplier to international markets, we see MICC Cables bought by electrical contractors, utility companies, and construction OEMs. They are a go-to for projects that require certification compliance and low maintenance over decades — a major selling point for wholesalers and bulk buyers concerned with total cost of ownership.

What are the disadvantages of MICC cable?

Cost and installation considerations

Compared with standard polymer-insulated cables, MICC Cables typically carry a higher upfront cost due to materials and manufacturing complexity. Installation can be more labor-intensive: the metal sheath and compacted core make the cable less flexible, requiring careful bending, specialized termination fittings, and experienced electricians to avoid damage during pulling or jointing.

Weight, flexibility, and joints

Mineral content and metal sheathing increase weight, which can impact shipping and handling for large orders. Flexibility is limited — long runs and tight bends need planning. Joints and terminations require proper gland sets and sealed fittings; if poorly executed, these are the weak points for moisture ingress. As a trusted Manufacturer, QRUNNING supplies complete termination kits and technical support to reduce on-site mistakes for Wholesaler and contractor clients.

How long does MICC last?

Expected service life

Under normal conditions and with correct installation, MICC Cables are renowned for exceptional longevity. Service lives of 40–60 years or more are commonly reported in industry practice for indoor, dry applications. In harsh or corrosive environments, selecting the correct sheath material (e.g., stainless steel) and following recommended installation and sealing practices is crucial to reach those lifespans.

Factors that influence lifespan

Key factors include operating temperature, mechanical stress, exposure to corrosives, quality of terminations, and compliance with installation standards. A reliable Supplier and Manufacturer will provide certification, installation guidance, and options for Customizable sheath materials and sizes — all of which extend real-world life and reduce lifecycle costs for bulk buyers and project owners.