Are You Choosing the Right High-Voltage Cable for Long-Term Power Reliability?

Are you facing frequent failures, unexpected losses, or compliance risks when sourcing cabo de alta tensão for critical power projects? Many contractors and Grossistas struggle because unsuitable materials, poor cable construction, or unreliable suppliers lead to overheating, insulation breakdown, and costly downtime. These issues often stem from limited manufacturing capability and inconsistent quality control. The solution is working with an experienced Fabricante that understands real-world electrical demands. With over 30 years of industry expertise, QRUNNING operates 10 advanced production lines and offers personalizável HV cable solutions, strict testing, and OEM & ODM services, ensuring stable performance, competitive pricing, and dependable global supply.

A high voltage cable is designed to safely transmit electrical energy at elevated voltage levels, typically above 35kV. It combines advanced insulation, precise conductor design, and durable shielding to ensure efficient power transfer, minimal losses, and long service life in demanding transmission environments.

To fully understand why HV cables are essential for modern electrical systems, it is important to explore their definition, working principles, and material choices in greater detail.

What Constitutes a High-Voltage Cable?

A cabo de alta tensão is an electrical cable engineered to carry power at voltages

significantly higher than standard distribution levels. In most applications, HV cables operate from 35kV up to 220kV, serving as a backbone for regional grids, industrial facilities, and infrastructure projects. Unlike low-voltage cables, HV designs must withstand intense electrical stress, temperature variation, and environmental exposure.

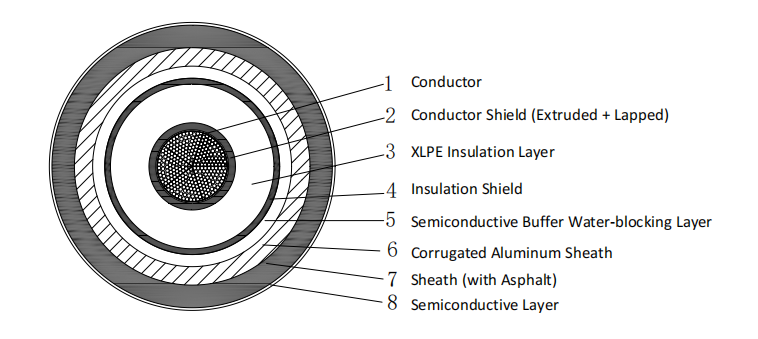

From a structural perspective, proper cable construction is critical. A typical HV cable consists of a conductor, inner semiconductive layer, insulation layer, outer semiconductive layer, metallic shielding, and protective sheath. Each layer plays a specific role in controlling the electric field, preventing partial discharge, and ensuring operational safety. As a professional Fornecedor, QRUNNING focuses on precision layering and material purity to deliver stable and long-lasting HV products.

For Grossistas and project buyers, understanding these components helps evaluate quality beyond price, reducing long-term maintenance and replacement risks.

How Do High-Voltage Cables Function?

Electrical Performance and Insulation Control

The primary function of a cabo de alta tensão is to transmit electrical energy efficiently while maintaining insulation integrity. When voltage increases, the electric field strength around the conductor rises sharply. Without proper insulation design, this can lead to discharge, energy loss, or insulation failure. High-quality HV cables use specially formulated insulation materials and smooth conductor surfaces to evenly distribute electrical stress.

Advanced cable construction techniques ensure that the electric field remains stable during operation. The semiconductive layers surrounding the insulation help eliminate air gaps and reduce field distortion. This design significantly extends service life, especially in underground or industrial installations.

Thermal and Mechanical Stability

In addition to electrical stress, HV cables must manage heat generated by current flow. Efficient thermal performance prevents overheating and aging of insulation materials. As an experienced Fabricante, QRUNNING designs HV cables to balance current capacity and heat dissipation, ensuring safe operation even under continuous load.

Mechanical strength is equally important. HV cables are often installed in challenging environments where vibration, tension, or bending forces are present. Reliable Fornecedores prioritize robust outer sheaths and armor options to protect the cable throughout its operational life.

Why Not Use Copper in High-Voltage Lines?

Weight, Cost, and Installation Challenges

Copper is widely known for its excellent conductivity, leading many buyers to question why it is not always used in HV transmission lines. While copper performs well electrically, it has notable drawbacks in high-voltage applications. Its higher density makes cables heavier, increasing transportation, handling, and installation costs—especially for long-distance projects.

From a cost perspective, copper prices fluctuate significantly in global markets. For Grossistas and contractors managing large-scale procurement, this volatility can impact budgets and bidding competitiveness. As a result, many Fabricantes offer aluminum-based conductors as a more economical and practical alternative.

Performance Balance and Customization

Aluminum conductors, when properly engineered, provide an effective balance between conductivity, weight, and cost. Modern cable construction techniques compensate for aluminum’s lower conductivity by optimizing conductor size and insulation design. This makes aluminum-based cabo de alta tensão suitable for most transmission needs.

QRUNNING, as a professional Fornecedor, offers personalizável conductor options based on project requirements, ensuring buyers receive the most cost-effective and technically appropriate solution without compromising safety or performance.

Conclusão

High voltage cables are essential for reliable power transmission. Understanding HV design, function, and material choices helps buyers select the right Supplier, reduce risk, and achieve long-term efficiency in demanding electrical projects.