Are You Finding It Difficult to Select the Right Armoured Cable for Tough Engineering Environments?

Many buyers struggle to identify the correct armoured cable because options like SWA, STA, and aluminium-based variants each serve different conditions. Misjudging these requirements can lead to cable failure, safety hazards, or costly project delays. These issues often arise from unclear specifications and inconsistent production quality. As a global Manufacturer, Wholesaler, and Supplier with 30+ years of expertise, QRUNNING delivers certified, durable, and personalizável steel-reinforced cable solutions to ensure long-term stability, safety, and efficiency in any installation environment.

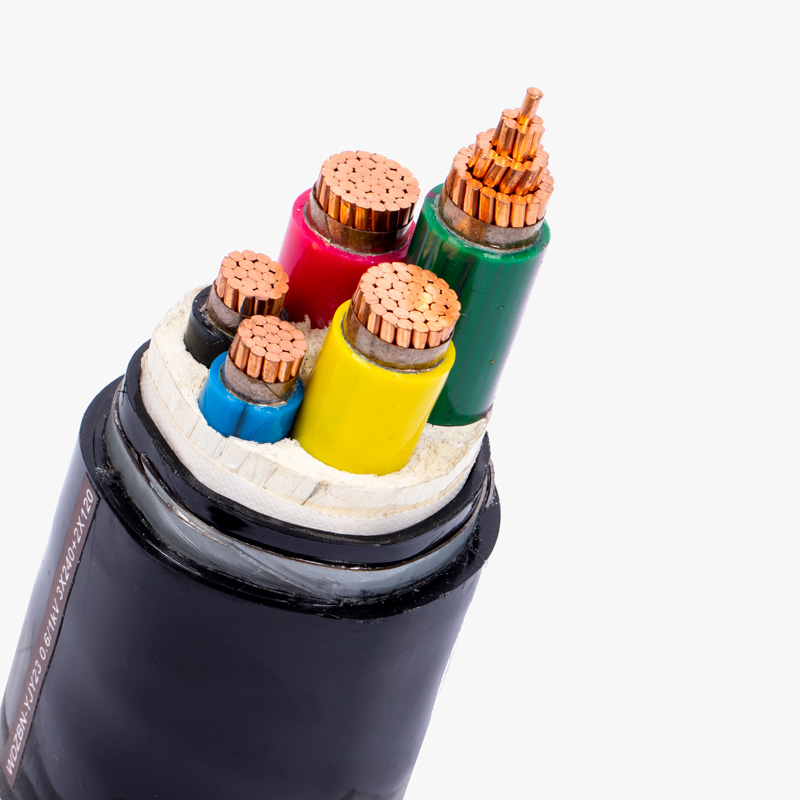

Armoured cables use layers of steel or aluminium to protect conductors from crushing, impact, moisture, and external stress. Types such as SWA, STA serve power distribution, industrial systems, and underground installations where durability and safety are essential.

This guide offers a clear, practical explanation of armoured cable types, structures, and benefits, helping you make confident and informed purchasing decisions.

Related products: Armored Cable – Qrunning is manufacturer of wires and cables in china

Ultimate Guide to Armoured Cable

An armoured cable is designed with a metal protective layer—usually steel or aluminium—placed between the insulation and outer jacket. This reinforcement gives the cable exceptional mechanical strength, making it suitable for underground routing, industrial installations, and areas exposed to heavy external pressure. As a specialised Manufacturer and Wholesaler, QRUNNING provides fully personalizável armoured constructions for low-voltage and medium-voltage power systems.

Different armouring methods serve different environments. Steel-based options (such as SWA and STA) deliver high impact resistance, while aluminium armouring reduces weight for non-ferrous applications. A reliable Supplier ensures the correct armouring type is paired with your installation method, soil conditions, mechanical load, and safety certifications—important factors that directly affect cable lifespan and site compliance.

Why Choose Armoured Cables? Safety and Strength Facts

Armoured cables offer significantly enhanced protection compared with unarmoured designs. The reinforced steel or aluminium structure prevents crushing, corrosion, and rodent damage, reducing the risk of electrical faults. They also provide stability during installation, especially across uneven terrain or where cables must withstand periodic movement. For demanding industrial and construction environments, a Manufacturer specialising in heavy-duty cables ensures consistent material quality.

Safety is a primary reason engineers choose armoured cables. The robust metal layer helps maintain conductor integrity under mechanical stress, reducing fire risks caused by damaged insulation. Variants like SWA and STA offer reliable protection for underground wiring and external circuits. Customisable options allow a trusted Wholesaler to tailor thickness, materials, or jacketing to suit climatic conditions, chemical exposure, or load requirements.

What do Abbreviations Like SWA, STA, and AWA Signify?

SWA – Steel Wire Armoured

SWA refers to Steel Wire Armoured cables, which use steel wires for tensile strength. These cables are ideal for installations requiring pulling power, mechanical protection, and resistance to external impact. As a Supplier and Manufacturer, QRUNNING offers personalizável SWA designs for power distribution in industrial sites, commercial developments, and buried routes.

STA – Steel Tape Armoured

STA refers to Steel Tape Armoured cables, reinforced with overlapping steel tape that resists compression but not tensile load. These are ideal for fixed, underground installations where crushing resistance is critical. A dependable Manufacturer can provide personalizável STA solutions tailored to civil engineering, utility networks, and building infrastructure.

AWA – Aluminium Wire Armoured

AWA stands for Aluminium Wire Armoured. It provides similar tensile protection but is lighter and non-magnetic, making it suitable for single-core cables where magnetic fields must be minimized. A Wholesaler can supply these cables for long-distance runs and high-current applications where reduced cable weight enhances installation efficiency.

Summary

Armoured cables deliver essential protection, strength, and reliability for demanding installations, offering long-lasting performance when sourced from a trusted Manufacturer or Wholesaler.