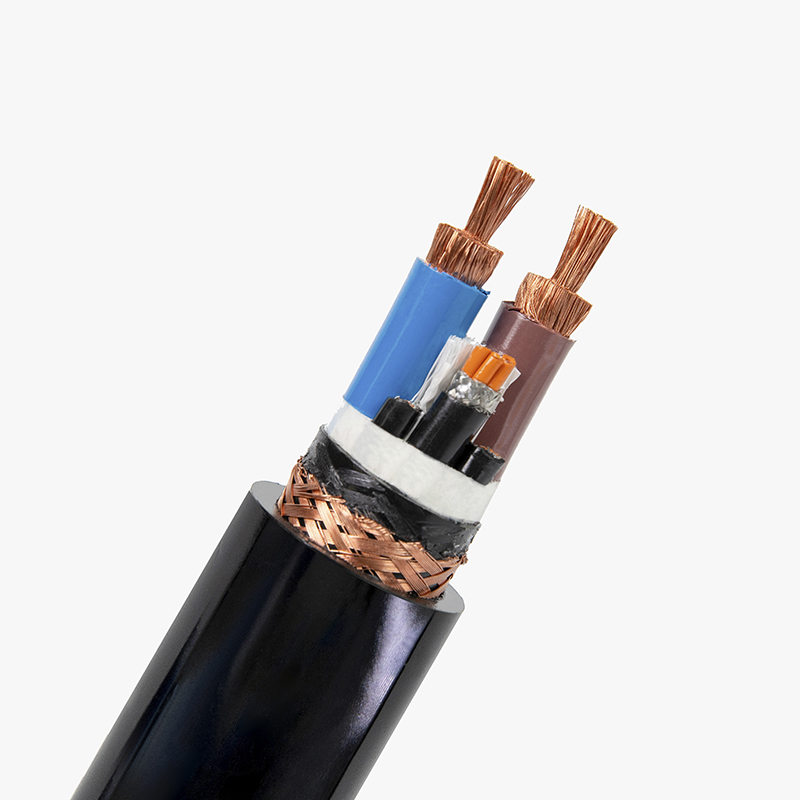

The central role of fillers: why can’t cables be “hollow”?

Fillers in cables are not just for appearance—they are essential to structure. When multiple conductors are stranded together, they leave natural gaps. Fillers occupy these voids, maintaining the cable’s round shape, preventing internal shifting, and ensuring uniform pressure distribution during insulation and jacketing. Without fillers, mechanical stress becomes uneven, increasing the risk of insulation rupture, deformation during bending, and reduced durability over time.

PP rope vs. hemp rope vs. water-resistant yarn: which is better?

Filler material directly affects a cable’s mechanical strength, weight, moisture resistance, and cost. Below is a performance comparison of three commonly used filler types in power cable manufacturing:

| Material | Mechanical Strength | Flexibility | Moisture Resistance | Cost | Application Suitability |

|---|---|---|---|---|---|

| PP Rope | High | Médio | Excellent | Baixo | General-purpose power cables |

| Hemp Rope | Médio | High | Poor | Médio | Traditional, low-voltage or indoor cables |

| Water-Resistant Yarn | Médio | Médio | Excellent (with water-blocking property) | High | High-voltage, water-prone environments |

PP rope is widely used due to its strength and moisture resistance at a competitive price. Hemp rope offers better flexibility but lacks durability in wet conditions. Water-resistant yarn, while costly, is crucial in high-performance cables exposed to water or underground installations.

How “roundness” affects cable formation quality

Maintaining a cable’s round shape is not just for appearance—it critically impacts the overall performance. A well-rounded cable ensures even insulation thickness and effective sheathing, avoiding weak points. Irregular shapes from poor filler selection lead to compression stress on conductors, improper heat dissipation, and insulation inconsistencies. Roundness also facilitates smoother cable laying, especially in ducts or trays, reducing the chance of installation damage. Proper filler design ensures dimensional stability from production to deployment.

Special filler designs for different cable types

Water-retardant cables: swelling yarns for barrier protection

Water-retardant fillers use super-absorbent polymer yarns that swell upon contact with moisture, forming a gel-like barrier. This prevents water from migrating along the cable core, protecting conductor integrity in underground or submersible installations.

Flexible cables: kink-resistant fillers

Flexible cables used in robotics or dynamic equipment rely on kink-resistant fillers—typically soft PP or textile-based ropes with enhanced elasticity. These fillers support repeated bending while minimizing internal stress and preventing conductor breakage.

Flame-retardant cables: synergy with low-smoke, halogen-free designs

In flame-retardant cables, fillers must not fuel combustion. Non-woven glass fiber or flame-inhibiting PP is used to enhance flame resistance and reduce smoke. These fillers complement LSZH compounds for safer cable installations in public buildings and tunnels.

Failure cases: poor filler choices and the consequences

A poor filler selection can lead to costly failures. One example involved a low-voltage cable installed in a tropical region using hemp rope as filler. Over time, humidity degraded the filler, leading to internal swelling and insulation rupture. In another case, a high-voltage submarine cable lacked water-swellable yarn. When a breach occurred, water penetrated the full length of the cable, causing a complete system shutdown. These failures emphasize that filler materials are not interchangeable and must match the cable’s application environment.

Summary and advice to customers

Cable fillers play a quiet but vital role. Always select fillers based on cable type, environment, and performance expectations. Consult professional suppliers like QRUNNING to ensure the right filler materials for long-term reliability.