Have you ever wondered why your cable systems fail earlier than expected?

Improper handling of cable bend radius is one of the most common causes behind premature damage in power and communication systems. When a cable is bent too tightly, it suffers internal stress, leading to cracks, reduced conductivity, or even total system breakdown. For large-scale projects, this means costly delays, safety risks, and equipment replacement. The solution lies in following correct minimum bend radius guidelines. As a leading manufacturer and wholesaler with over 30 years of experience, QRUNNING offers premium-quality cables up to 500kV, backed by certified testing, advanced production lines, and customisable solutions for global distributors and contractors.

The cable bend radius is the minimum radius a cable can be bent without causing damage, ensuring long-term performance and safety in power and communication systems.

Understanding this principle is essential for every supplier, distributor, or engineering contractor. Let’s explore the key details of cable bend radius and why it matters.

How to Determine the Bending Radius of a Cable?

The minimum bend radius is typically defined by the cable’s outer diameter and its construction type. For example, flexible cables allow tighter bends than rigid, high-voltage power cables. Industry standards often express bend radius as a multiple of the cable’s diameter. A common rule is 10–15 times the diameter for shielded power cables, while fiber optic cables may require even larger bend allowances. To determine the correct radius, you should always consult the cable manufacturer’s datasheet or international standards. At QRUNNING, we provide clear technical documentation and OEM/ODM customisable support to help buyers apply the correct specifications for their projects.

Why is Cable Bend Radius Critical?

The cable bend radius directly impacts performance, longevity, and safety. Bending a cable beyond its tolerance introduces excessive tension and compression forces within its layers. This can compromise insulation, distort conductors, and increase electrical resistance. For high-voltage projects, it may lead to partial discharges or dangerous short circuits. For data or fiber cables, improper bending degrades signal integrity, causing interference or data loss. Contractors and suppliers who overlook this principle risk costly rework, equipment failure, and reputational damage. Following the correct bend radius ensures consistent quality, reliable power transmission, and compliance with safety standards.

Factors Influencing Bend Radius

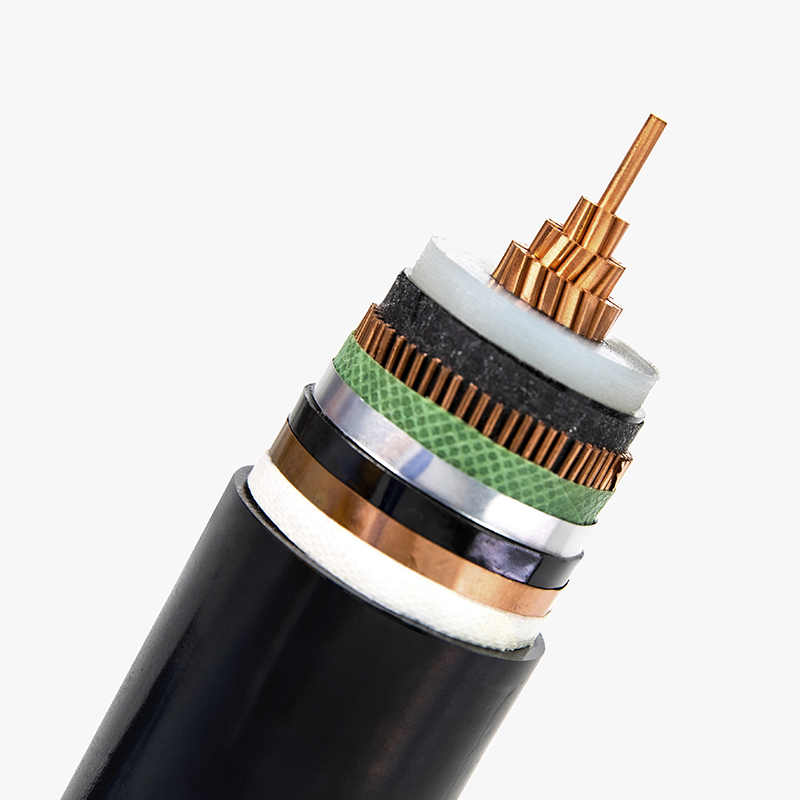

1. Cable Construction

The number of conductors, shielding layers, and insulation thickness all influence how tightly a cable can bend. Multi-core armored cables require larger bend radii compared to simple unarmored wires.

2. Material Properties

The flexibility of copper, aluminum, or optical fibers, as well as insulation compounds, determine the level of bending stress a cable can withstand without failure.

3. Cable Diameter

Thicker cables naturally need a larger radius. A 100mm diameter high-voltage power cable cannot bend as tightly as a thin control cable without causing mechanical damage.

4. Installation Environment

Temperature fluctuations, pulling tension during installation, and confined spaces can all influence the effective bend radius. Professional suppliers always account for these conditions when designing projects.

Consequences of Excessive Wire Bending

Exceeding the minimum bend radius has serious consequences. Mechanical stress can cause conductor strands to fracture, insulation layers to crack, and shielding to loosen. Over time, this reduces cable lifespan and reliability. In high-voltage systems, it increases the risk of electric arcing and short circuits. In communication systems, improper bending leads to signal attenuation, interruptions, or complete transmission failure. These outcomes translate into increased maintenance costs, unplanned downtime, and even safety hazards. For distributors, faulty installations caused by incorrect bend radius can harm credibility and lead to contractual disputes with clients.

What is the Minimum Bend Radius?

The minimum bend radius is the smallest radius to which a cable can be bent safely without damage. It is usually calculated as a multiple of the cable’s diameter, varying with insulation type and construction. For example, a cable with a 20mm diameter and a bend radius requirement of 12 times its diameter should not be bent tighter than 240mm. This guideline ensures mechanical integrity and electrical performance remain intact throughout the cable’s service life. At QRUNNING, as an experienced manufacturer and wholesaler, we ensure all our power cables meet international standards, offering dependable quality to global engineering contractors and distributors.

What is Bending Stress?

Bending stress is the internal force experienced by a cable when bent. It results from compression on the inner curve and tension on the outer curve of the cable. If this stress exceeds material limits, it leads to permanent deformation or structural failure. Understanding bending stress is vital when routing cables around tight corners, inside conduits, or during transportation and storage. Engineering contractors should always work with certified suppliers that provide accurate bending stress data, ensuring safe and efficient installations. With QRUNNING’s advanced production technology and strict quality control, customers can trust that every cable is designed to withstand appropriate bending stress without compromising reliability.

Conclusion

Respecting the cable bend radius safeguards quality, extends cable life, and prevents costly failures. Always follow manufacturer guidelines to ensure reliable performance and safety.