Flexible mineral insulated cable is a specialized power cable designed for high-temperature resistance, fire safety, and durability. Unlike traditional power cables, it uses inorganic mineral insulation, typically magnesium oxide (MgO), which makes it highly fire-resistant and stable even under extreme conditions.

Key characteristics of Mineral Insulated Cable cables include:

- High temperature resistance:Can withstand temperatures up to 1000°C without losing functionality.

- Fire safety:Maintains power transmission during fires, making it ideal for emergency systems.

- Moisture and corrosion resistance:The mineral insulation prevents water ingress and offers excellent chemical resistance.

- Low smoke, halogen-free:Inorganic materials prevent the release of toxic gases during fires.

- Flexibility:Unlike traditional mineral insulated cables, Flexible Mineral Insulated cables have a more flexible design, making installation easier.

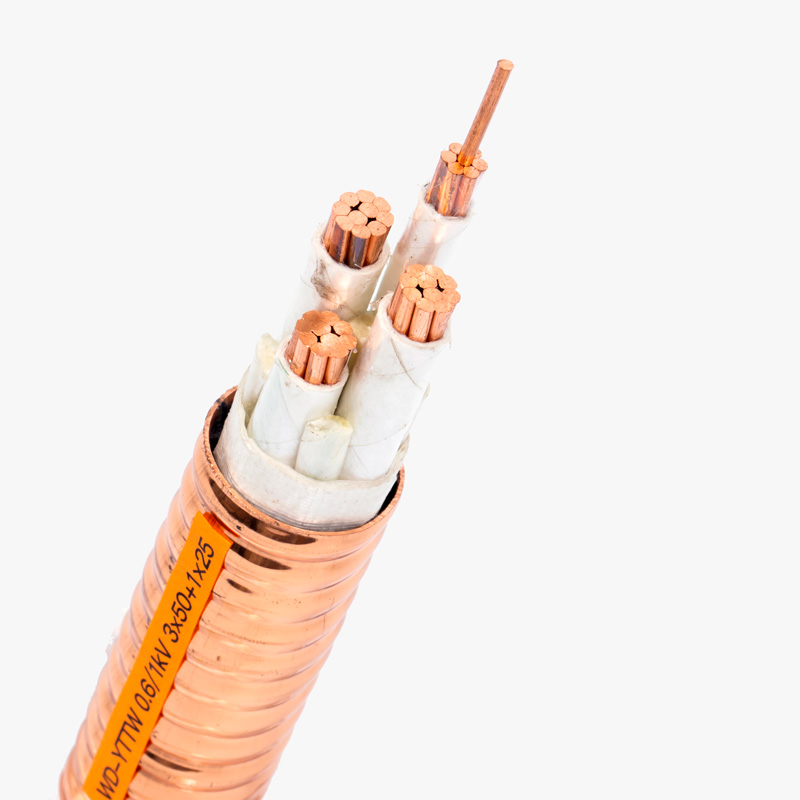

FMI cables consist of the following layers:

- Conductor:Usually made of copper or nickel-plated copper, providing excellent conductivity and mechanical strength.

- Insulation layer:Made of compressed magnesium oxide (MgO), which offers superior fire and heat resistance.

- Metal sheath:Often made of copper or alloy, providing mechanical protection, moisture resistance, and acting as a grounding conductor.

- Flexible outer sheath:In Mineral Insulated cables, a flexible metallic or polymer sheath is applied, making them easier to install compared to traditional rigid mineral insulated cables.

Flexible mineral insulated cables are widely used in:

- Fire protection systems:Emergency power lines, fire alarm systems, and evacuation lighting.

- Industrial environments:High-temperature areas such as steel plants, chemical factories, and oil refineries.

- Critical infrastructure:Tunnels, subways, hospitals, and data centers, where fire-resistant cabling is essential for safety.

- Nuclear power plants:Due to their radiation resistance and fireproof characteristics.

FMI cables were developed to address the limitations of conventional plastic-insulated cables in high-risk environments. Standard XLPE or PVC-insulated cables:

- Melt or degradeunder high temperatures.

- Release toxic smokewhen burned, which is hazardous during fires.

- Have limited fire survival time, making them unreliable in emergencies.

To overcome these issues, FMI cables were introduced. Their inorganic insulation prevents combustion, ensuring continuous power supply even in fire conditions, making them indispensable for fire safety and emergency circuits.

Differences Between FMI Cable and XLPE Cable

| Feature | Flexible Mineral Insulated Cable (FMI) | XLPE Insulated Power Cable |

| Insulation material | Magnesium oxide (MgO) – inorganic, fireproof | XLPE (cross-linked polyethylene) – organic polymer |

| Fire resistance | Can withstand up to 1000°C, continuous operation | Degrades at around 90°C-105°C |

| Smoke emission | Low smoke, halogen-free, no toxic gases | May emit toxic smoke during combustion if using non LSZH material |

| Flexibility | Flexible design for easier installation | Less flexible, especially in larger sizes |

| Durability | Resistant to moisture, corrosion, and chemicals | Less resistant to water and chemical exposure |

| Application | Fire safety, emergency systems, and industrial | General power distribution |

Flexible mineral insulated cables offer superior fire resistance, durability, and safety compared to standard XLPE cables. Their ability to maintain power transmission in extreme conditions makes them the preferred choice for critical applications, such as fire safety systems and high-risk industrial environments.