No sooner had the typhoon passed than the scorching heat of the “dog days” swept in again. During this peak season for power transmission cables, frontline workers are facing a critical production challenge—maintaining high output despite extreme temperatures. Undeterred by the sweltering conditions, they stand firm at their posts, ensuring timely order fulfillment.

At noon, our team visited the workshop, where temperatures had already reached 35°C (95°F) amid the heat radiating from running machinery. Yet, the workers pressed on—transporting materials, operating equipment, recording production data—every process running smoothly despite the oppressive heat.

Near the 200-type extruder, the air hung thick and humid like a damp cloth. The high-speed machine exhaled gusts of hot air, adding to the stifling atmosphere. Sweat trickled down an operator’s face beneath his hard hat, soaking into his collar, but he had no time to wipe it away—his left hand steadied freshly extruded cable while his right adjusted cooling water valves, ensuring the insulation layer solidified perfectly under the spray. Only during brief pauses could he step over to a fan for a quick sip of cool water.

“With this heatwave and urgent orders piling up, we’re running nonstop production schedules—24/7 at full capacity,” said Yang Xingheng, head of the No. 2 Plant. “Thankfully, the company has provided ample cooling drinks and heatstroke prevention supplies to keep everyone safe and healthy.”

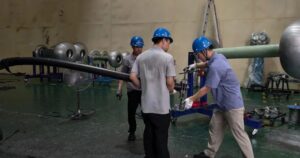

Beside the 500kV partial discharge test equipment, our team observed inspectors, clad in safety helmets and protective gloves as usual, preparing for another rigorous examination. Inside the sweltering testing room, they meticulously carried out pre-test procedures—checking cable surfaces (for damages or deformations), inspecting terminations (sleeves and accessories), and cleaning off contaminants to ensure all insulating components were dry and spotless. Within minutes, their uniforms were already drenched in sweat.

“The production schedule is tight, but quality control remains our top priority,” emphasized the testing team leader. “Having recently secured major contracts from State Grid and China Southern Grid, we’re acutely aware of our responsibility. Every single cable leaving Qiuguan’s facility must meet the highest safety standards—our clients’ trust depends on it!”

The equipment maintenance team stands resolute in the scorching temperatures, working around the clock to ensure uninterrupted machinery operation. Meanwhile, logistics crews brave the blazing sun in outdoor storage yards, carefully loading cable reels onto trucks destined for power construction sites nationwide. Their uniforms soaked through with sweat, their eyes remain sharp with focus and determination.

Through seamless coordination, they overcome every heat-induced challenge, demonstrating remarkable teamwork and resilience. “Battle the heat, maximize output, secure deliveries” — these tireless warriors embody this motto through their actions. Every drop of sweat speaks of their dedication; every silent effort fuels the company’s high-quality development.

Salute to you, our frontline heroes! You are the most admirable industrial workforce of the new era – turning scorching adversity into operational excellence with unwavering commitment.