How can you ensure the reliability and safety of your triple-core medium voltage cables?

For electrical engineers, project managers, and contractors in the power distribution industry, ensuring the quality and reliability of triple-core medium voltage cables is crucial to avoid costly delays, system failures, and safety risks. Faulty cables, whether due to poor insulation or inadequate material quality, can cause major disruptions in power networks, leading to unplanned shutdowns and project delays. The solution lies in adhering to stringent testing standards and quality control protocols at every stage of cable production. As a trusted wholesaler and supplier, QRUNNING ensures that every triple-core medium voltage cable is manufactured under strict guidelines, using rubber or XLPE insulation for enhanced safety and performance.

To maintain the highest quality, triple-core medium voltage cables must undergo rigorous testing in accordance with established international standards, ensuring reliable performance in power grid and industrial applications.

Read on to explore the core testing items, key quality control points, and quality acceptance standards that guarantee the performance of triple-core cables in various power applications.

Core Testing Items and Implementation Standards for Triple-Core Medium Voltage Cables

The quality of triple-core medium voltage cables is ensured through a series of comprehensive core testing procedures. These tests assess the cable’s overall performance, safety, and durability. Common testing items include voltage withstand tests, insulation resistance tests, conductor resistance tests, and partial discharge tests. Each test is conducted in compliance with international standards such as IEC (International Electrotechnical Commission) and ASTM (American Society for Testing and Materials).

Voltage withstand tests check the cable’s ability to endure high-voltage surges without failure, simulating real-world conditions. Insulation resistance tests measure the effectiveness of the insulation, while conductor resistance tests evaluate the efficiency of the copper conductors in transmitting current. Additionally, partial discharge tests identify potential weaknesses in the insulation that may lead to future breakdowns. These testing procedures ensure that triple-core medium voltage cables meet the current capacity and safety requirements necessary for power grid and industrial applications.

Key Quality Control Points in the Production Process of Triple-Core Medium Voltage Cables

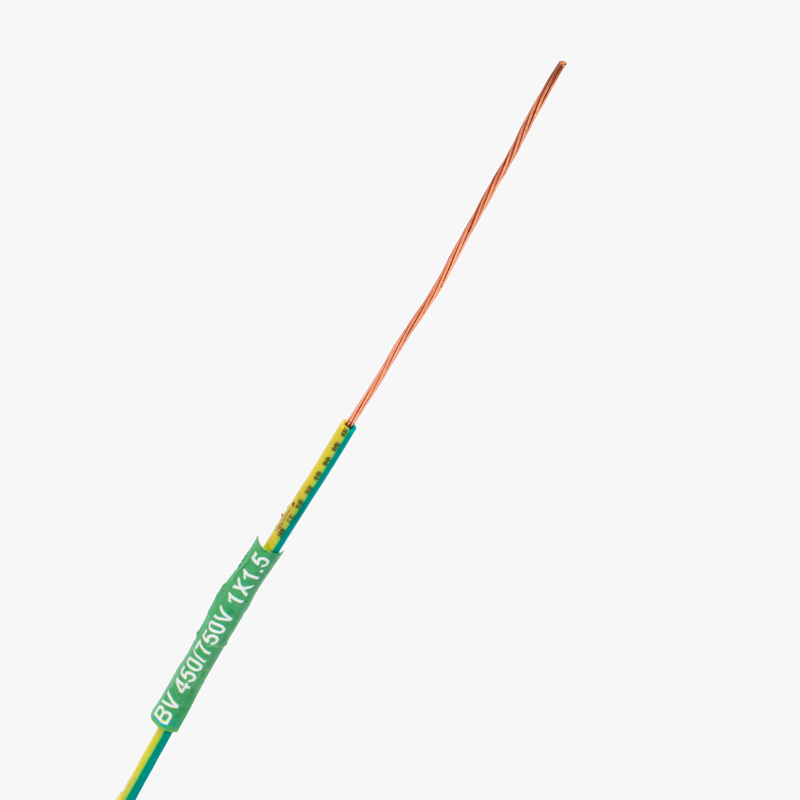

Effective quality control during production is vital to ensure the reliability of triple-core medium voltage cables. Several key points in the production process demand attention, such as the quality of raw materials, precision in manufacturing, and the curing process. The choice of materials—whether rubber, PVC, or XLPE—plays a critical role in the final performance of the cable. Copper conductors must be of high purity to ensure efficient energy transmission, while the insulation material must meet stringent electrical and mechanical standards to withstand environmental stress.

The manufacturing process involves careful extrusion of the conductor and insulation layers. Once the insulation is applied, the cables undergo a curing process to ensure it adheres properly to the conductors. QRUNNING, as a customizable cable manufacturer, offers tailored solutions to meet specific industry needs, whether for outdoor installations or underground applications, ensuring each batch meets or exceeds regulatory standards.

Quality Acceptance Specifications for Triple-Core Medium Voltage Cables in Power Grid Applications

Power grid applications demand high standards for electrical performance and longevity. QRUNNING, a trusted supplier in the global market, adheres to the latest quality acceptance criteria to guarantee the reliability of our triple-core cables under demanding conditions. Our customizable products are designed to meet the unique requirements of each installation, ensuring safety and minimal operational disruption.

Impact of Material Quality on Testing Performance of Triple-Core Medium Voltage Cables

The material quality used in triple-core medium voltage cables significantly affects their testing performance. High-quality copper conductors, rubber or XLPE insulation, and PVC jacketing materials contribute to the overall durability and electrical efficiency of the cable. Poor-quality materials can lead to excessive resistance, higher heat generation, and potential cable failure, particularly under medium voltage stress.

QRUNNING sources only the finest materials, ensuring that copper conductors meet international purity standards and that the insulation is thick enough to provide optimal protection against electrical faults, physical damage, and environmental factors. When combined with strict testing standards, the result is a cable that provides reliable, long-term performance in power grids, industrial plants, and other high-demand applications.

Conclusion

In conclusion, triple-core medium voltage cables must pass rigorous testing and meet high-quality standards to ensure safety, reliability, and efficiency in power distribution systems. With the right materials and manufacturing processes, these cables offer long-lasting performance, meeting the demands of modern electrical networks.