Are You Struggling to Source Reliable High Voltage Cables for Your Projects?

Many construction companies, distributors, and power engineering contractors face the same issue: sourcing high voltage cables that meet strict quality standards, arrive on time, and come with trusted certification. Poor-quality cables can cause delays, safety risks, and financial losses. The solution lies in working with an experienced manufacturer and supplier. With over 30 years of industry expertise, QRUNNING offers top-quality HV cables, customizable designs, and OEM & ODM services. Our factory operates 10 advanced production lines, delivering up to 200 million meters annually. As a leading Chinese wholesaler, we ensure timely delivery, strict quality control, and competitive prices for global partners.

High voltage cables are essential for safe and efficient power transmission, designed to handle large amounts of electricity across long distances while ensuring durability, reliability, and consistent performance.

To better understand the importance of HV cables, let’s explore their definition, applications, features, and types, and see why choosing the right supplier makes a critical difference.

What are High Voltage Cables?

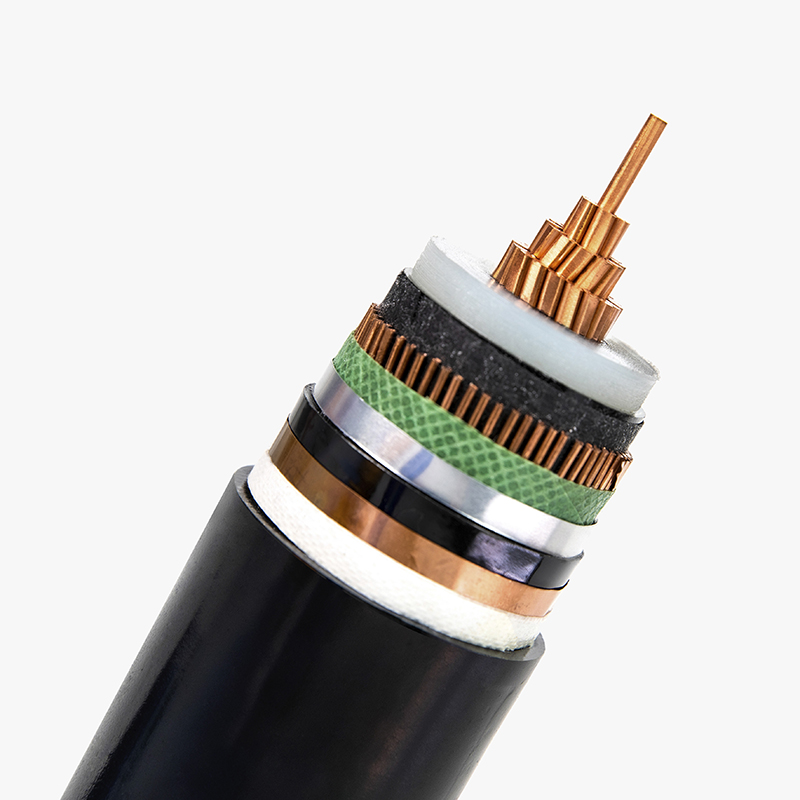

High voltage cables, often called HV cables, are specially designed to transmit electrical energy at voltages above 35kV. These cables are constructed with a central conductor made of copper or aluminum, surrounded by insulation layers, semiconducting screens, and protective armour. The purpose of this design is to prevent breakdown, reduce power loss, and ensure reliable long-distance transmission. Unlike low-voltage cables, HV cables must withstand high electrical stress, environmental factors, and mechanical forces. A trusted manufacturer will always test these cables under strict international standards to guarantee safety and performance.

Read more:https://www.qrunningcable.com/portfolio_category/high-voltage-cable-products/

What are the Typical Applications of High Voltage Cables?

The use of HV cables spans across industries and infrastructure projects. They are vital in power grid systems, connecting generating stations to substations and substations to distribution net

works. In industrial projects, they power heavy machinery and ensure continuous operations in factories. Construction and engineering

contractors rely on high voltage cables for tunnels, airports, railways, and large-scale real estate developments. For renewable energy, such as wind farms and solar plants, these cables are crucial for transmitting clean energy to urban centers. A reliable supplier ensures that each cable is designed for specific environments, whether underground, underwater, or overhead installations.

What are the Key Features of High Voltage Cables?

Several key features make HV cables stand out. Firstly, they provide excellent electrical conductivity through high-quality conductors. Secondly, advanced insulation materials ensure thermal stability and resistance to electrical stress. Thirdly, the addition of armour enhances mechanical strength, making the cable resistant to external pressure and accidental damage. Furthermore, these cables are designed for long service life, minimal maintenance, and consistent performance in harsh environments. Reliable manufacturers and suppliers also offer customisable designs to meet the unique requirements of specific projects, ensuring compatibility with different voltage levels and installation conditions.

Where High Voltage Cables Make a Critical Difference?

The role of high voltage cables is often underestimated until failure occurs. In critical sectors such as healthcare facilities, transport infrastructure, and national power grids, these cables ensure uninterrupted electricity supply. In developing regions, where stable power is essential for economic growth, HV cables provide the backbone of new infrastructure. Engineering contractors also find that choosing the right supplier reduces the risk of delays caused by poor-quality materials. In large-scale tenders, reliable HV cable manufacturers offer certified solutions that increase the competitiveness of contractors while guaranteeing long-term performance and safety

What are the Different Types of High Voltage Cables?

There are several types of HV cables, each designed for specific conditions. XLPE (Cross-Linked Polyethylene) cables are widely used due to their excellent thermal and electrical properties. PILC (Paper-Insulated Lead-Covered) cables are traditional designs still used in certain applications, known for their durability. OF (Oil-Filled) cables are applied where extra cooling is needed for high-capacity transmission. In addition, there are specialized armoured cables for underground and underwater installations, providing both protection and reliability. A professional manufacturer or wholesaler will recommend the right type based on the project’s voltage, location, and budget, ensuring optimal performance.

Conclusion

High voltage cables are the foundation of modern power systems. Choosing a trusted manufacturer and supplier ensures quality, safety, and long-term value for any project.