What are the Types of Underground Cables?

Underground cables are categorized based on insulation material, voltage level, and design. These variations ensure the right match for different industrial and infrastructural needs.

Read more:https://www.qrunningcable.com/portfolio_category/armored-cable/

Low Voltage UG Cable

This type of cable is commonly used in residential or commercial settings for distributing power up to 1kV. It ensures safety in urban environments where overhead wires may cause accidents.

Medium Voltage UG Cable

Operating between 1kV and 33kV, these cables are ideal for industrial zones and regional networks. They offer greater durability and efficiency, supporting continuous power transmission under demanding conditions.

High Voltage and Extra-High Voltage UG Cable

Designed for power grid companies and long-distance transmission, these cables can handle voltages up to 500kV. Their insulation and protection layers, such as armoured cable, provide excellent mechanical strength and safety for underground applications.

Specialty Underground Cables

In addition to standard types, there are oil-filled and gas-insulated cables for extremely high-voltage projects. QRUNNING offers customisable designs to meet specific project requirements, ensuring optimal performance in diverse environments.

Benefits of Underground Cable Laying

Switching to underground cables provides multiple advantages for modern infrastructure projects:

Enhanced Safety

Unlike overhead lines, UG cables are shielded from storms, lightning, and external contact, significantly lowering the risk of accidents and outages.

Reduced Maintenance Costs

While initial installation may be higher, maintenance expenses over time are greatly reduced. Underground networks last longer and require fewer interventions, cutting costs for suppliers and contractors.

Aesthetic and Environmental Benefits

Buried cables eliminate visual clutter, preserving urban aesthetics. They also reduce environmental disruption and the need for constant repair after natural disasters.

Reliable Power Transmission

With consistent voltage regulation and minimal exposure to external elements, UG cables ensure dependable power transmission for industries, factories, and cities.

Underground Electrical Cable Installation Standards

Following proper standards ensures durability, safety, and compliance in underground cable projects. Industry guidelines cover trenching, cable spacing, and protective coverings.

Depth and Trenching

Cables must be laid at recommended depths to avoid damage from construction activities. Protective layers such as sand, tiles, or warning tapes are used to enhance safety.

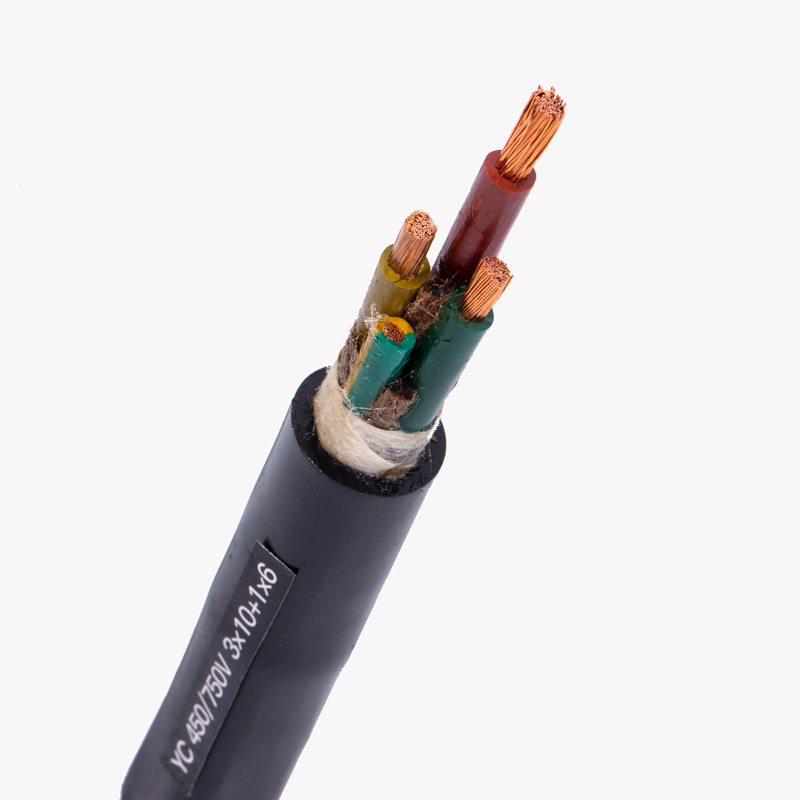

Insulation and Armouring

Armoured cable is essential for projects where cables are exposed to mechanical stress. Proper insulation materials, like XLPE or PVC, provide resistance against moisture and chemical corrosion.

Testing and Certification

Before commissioning, cables undergo rigorous testing, including insulation resistance and high-voltage checks. At QRUNNING, we ensure that every underground cable meets international standards and client-specific requirements.

Compliance and Documentation

Accurate certification and compliance with local regulations are vital. As a trusted wholesaler and supplier, QRUNNING guarantees authentic certifications and complete technical support, preventing risks from falsified documents.

Conclusion

UG cables provide a future-ready solution for reliable, safe, and efficient power transmission. Partnering with an experienced manufacturer like QRUNNING ensures quality, compliance, and project success.