What Are the Main Reasons for Wire and Cable Insulation Breakdown?

Have you ever faced sudden equipment failure caused by insulation breakdown in wires or cables? This common issue can lead to costly downtime, fire hazards, and serious safety risks. The causes often include poor-quality materials, improper installation, or harsh environmental conditions. As a trusted manufacturer and supplier with over 30 years of experience, QRUNNING provides certified, high-performance cables designed to prevent breakdown. With 10 production lines, customizable solutions, and strict quality inspections, we ensure durable products that help contractors, distributors, and power companies avoid unnecessary risks and project delays.

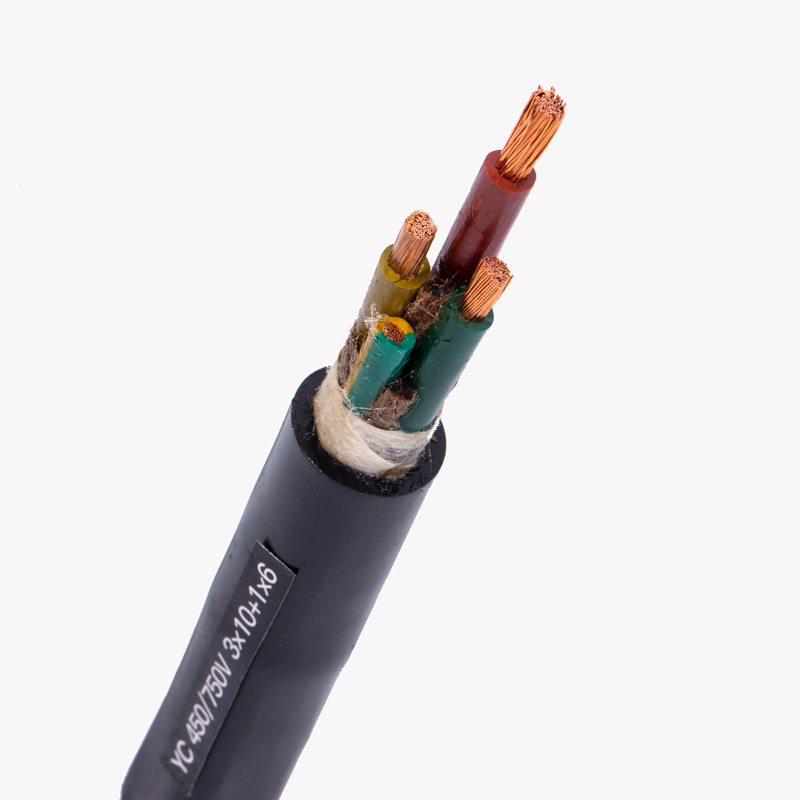

Wire and cable insulation breakdown occurs when protective layers lose effectiveness due to heat, moisture, mechanical stress, or poor materials. Choosing a reliable manufacturer and supplier ensures safety, longer service life, and reduced project risks.

Understanding the Causes is the First Step

Insulation problems rarely happen overnight. By exploring the key reasons behind insulation breakdown, buyers and engineers can make smarter sourcing decisions, protect investments, and extend cable performance.

Overview of Insulation Breakdown

Insulation breakdown refers to the loss of a cable’s protective barrier, allowing electricity to leak, short-circuit, or cause dangerous overheating. This can occur in low, medium, or high-voltage applications, making it a universal concern across industries. Once breakdown starts, it spreads quickly, often resulting in equipment damage, power interruption, or even fire. For wholesalers, contractors, and utility companies, sourcing from a proven manufacturer is critical to reducing these risks. QRUNNING addresses these challenges by combining advanced production technology with strict quality control, ensuring every product meets international safety standards.

| Aspect | Details |

|---|---|

| Definition of Insulation Breakdown | Loss of a cable’s protective barrier, allowing electricity to leak, short-circuit, or overheat dangerously. |

| Voltage Applications | Can occur in low, medium, or high-voltage cables, making it a concern across all industries. |

| Consequences | Rapid spread leading to equipment damage, power interruptions, or fire hazards. |

| Impacted Buyers | Wholesalers, contractors, and utility companies face risks without reliable sourcing. |

| QRUNNING’s Solution | Advanced production technology, strict quality control, and international safety certifications to ensure durable and safe products. |

Main Reasons for Wire and Cable Insulation Breakdown

Poor Quality Raw Materials

One of the leading causes of insulation breakdown is the use of low-grade materials. Inferior plastics or rubber compounds lose flexibility, crack, or harden over time. Some unreliable suppliers may cut costs by using recycled or uncertified materials, creating cables with a much shorter lifespan. At QRUNNING, we select only premium compounds that provide resistance to heat, chemical exposure, and mechanical stress. As a professional manufacturer and wholesaler, our cables are customizable to meet specific voltage, environment, and safety requirements.

Excessive Heat and Overloading

Heat is a major factor that accelerates insulation breakdown. When a cable is overloaded or placed in environments with high ambient temperatures, the insulation deteriorates faster. Prolonged overheating can cause insulation to soften, melt, or carbonize, leading to short circuits or fire hazards. To address this, QRUNNING designs cables with advanced heat-resistant insulation and carefully tested current ratings. Choosing the right supplier ensures you receive cables that operate safely under load without risking premature failure.

Moisture and Environmental Exposure

Moisture intrusion is another frequent cause of insulation breakdown. Water or humidity can seep into the insulation, causing swelling, cracking, or even electrical leakage. In coastal areas or underground installations, the risk is even higher. QRUNNING applies robust waterproofing measures and protective sheathing to guard against environmental stress. As a trusted manufacturer for international projects, we provide solutions tailored to diverse climates, ensuring stable performance in Africa, Southeast Asia, and beyond.

Mechanical Stress and Physical Damage

Improper handling, bending, or accidental impact can create micro-cracks in insulation that eventually spread into full-scale insulation breakdown. Construction sites, mining operations, and heavy industrial environments often expose cables to mechanical stress. Using reinforced insulation materials and advanced protective layers, QRUNNING delivers products designed for tough conditions. Distributors and contractors benefit from our customizable solutions that balance flexibility with durability, reducing the risk of unexpected failures.

Chemical Exposure and Corrosion

Certain installations expose cables to chemicals, oils, or corrosive gases that can slowly degrade insulation layers. Over time, this chemical attack reduces insulation thickness and compromises safety. High-quality manufacturing with tested resistance compounds is essential in such cases. QRUNNING, as a professional supplier, provides customizable cables engineered to resist specific chemical environments, helping clients safeguard equipment and ensure reliable power transmission.

Poor Installation Practices

Even the best materials cannot prevent insulation breakdown if installation is done incorrectly. Excessive pulling force, sharp bends, or poor termination can damage insulation from the start. At QRUNNING, we not only provide high-quality cables but also technical guidance for proper installation. As a long-term manufacturer and wholesaler, we support contractors with expertise that minimizes installation errors and maximizes cable lifespan.

Conclusion

Insulation breakdown is preventable with the right materials, proper installation, and a reliable manufacturer. QRUNNING ensures safer, longer-lasting cables for global projects.