Are You Unsure Which Cable Jacket Material Best Fits Your Project Needs?

Many buyers struggle to choose the right cable jacket because materials like PVC, PE, and LSZH each offer different levels of durability, fire resistance, and flexibility. Selecting the wrong type can cause premature failures, safety risks, and unexpected maintenance costs.

Cable jacket materials include PVC, PE, LSZH, rubber, and specialized compounds. Each jacket type protects the cable from mechanical stress, chemicals, and environmental exposure while ensuring long-term performance in industrial and power applications.

This guide helps you understand cable jacket materials clearly and choose the best option for your engineering, power, or industrial installations.

What is a Cable Jacket

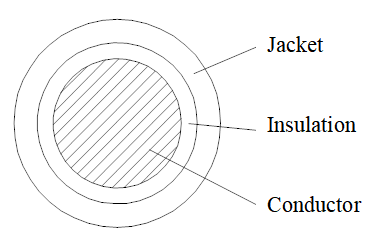

A cable jacket is the outermost protective layer surrounding insulated conductors and shielding components. It acts as a barrier against environmental and mechanical influences that can damage the cable throughout its service life. For cables produced by a professional Manufacturer or Wholesaler, the jacket is carefully designed to match operational demands such as flexibility, temperature resistance, chemical exposure, or outdoor durability. Common material options include PVC, PE, and LSZH, each selected based on performance and safety requirements. A reliable Supplier will ensure that the chosen jacket aligns with international standards and the intended installation environment.

The jacket also differentiates one cable category from another. For example, industrial control cables often use PVC for economy and general protection, while outdoor or direct-buried cables may require PE for superior moisture and abrasion resistance. In high-occupancy buildings, LSZH is chosen to reduce fire-related hazards. The design and composition of the jacket directly influence the cable’s longevity, safety, and compliance with engineering specifications.

What are the Types of Cable Jacket Materials

PVC Jackets

PVC (Polyvinyl Chloride) is one of the most commonly used jacket materials. It is valued for its affordability, flame resistance, flexibility, and resistance to oils and chemicals. PVC jackets are widely applied in indoor power cables, control cables, and instrumentation cables. As a Wholesaler and Manufacturer, we provide multiple PVC formulations—soft, standard, and flame-retardant—ensuring compatibility with diverse project requirements.

Related product:Copper Core PVC Insulated Flexible Wire 450/750V – Qrunning is manufacturer of wires and cables in china

PE Jackets

PE (Polyethylene) jackets are highly resistant to moisture, impact, and environmental stress cracking. They offer excellent dielectric strength, making them ideal for outdoor, underground, and direct-burial installations. PE jackets also provide superior longevity in harsh climates. Clients sourcing through a trusted Supplier can choose from LDPE, MDPE, or HDPE depending on the specific mechanical and environmental needs.

Related products:XLPE Insulated Electric Power Cable 500kV – Qrunning is manufacturer of wires and cables in china

LSZH Jackets

LSZH (Low Smoke Zero Halogen) materials are designed for fire-critical environments such as tunnels, commercial buildings, and transportation systems. LSZH jackets release minimal smoke and do not emit toxic halogen gases during combustion, significantly improving evacuation safety. At QRUNNING, our customisable LSZH compounds comply with strict international standards to meet modern building safety regulations.

Related product:Class B1 Low Smoke Zero Halogen (LSZH) flame Retardant Electrical Power Cable 26/35kV – Qrunning is manufacturer of wires and cables in china

Rubber and Special Compound Jackets

Rubber jackets—such as neoprene, chloroprene, and EVA—offer exceptional flexibility and weather resistance. These jackets perform well in dynamic, high-mobility environments, including mining, marine operations, and industrial machinery. Additionally, special jacket compounds may include UV-resistant blends, oil-resistant elastomers, or high-temperature materials tailored for extreme installations.

Related product:Rubber sheathed flexible cable for mine 8.7/10kV – Qrunning is manufacturer of wires and cables in china

The Function of the Jacket

The primary function of a cable jacket is to shield internal components from physical stress, environmental factors, and chemical exposure. It prevents moisture ingress, UV damage, abrasion, and corrosion that can compromise the cable’s electrical performance. For industries such as construction, energy, and automation, using a cable with a high-quality jacket ensures safer operation and reduces maintenance frequency.

Cable jackets also enhance safety in fire-sensitive zones. Materials like LSZH produce minimal smoke and halogen gases, offering additional protection in tunnels, public facilities, and enclosed buildings. Meanwhile, PVC jackets offer a cost-effective balance of flexibility, flame resistance, and durability, making them a top choice for general industrial wiring. PE jackets excel in environments requiring strong moisture resistance and impact tolerance.

Properties of Cable Jackets

Every jacket material comes with distinct mechanical, thermal, electrical, and environmental properties. PVC jackets are known for flexibility, flame retardancy, and resistance to oils and chemicals, making them widely used in indoor and industrial settings. PE jackets feature excellent dielectric properties, low moisture absorption, and high impact strength, making them suitable for outdoor or direct burial applications. LSZH jackets are engineered to reduce toxic emissions and smoke during combustion, ensuring compliance with strict building safety regulations.

A cable jacket must also maintain performance across various temperatures. PVC performs well in general temperature ranges, while PE offers better cold resistance. LSZH compounds provide stable performance in controlled environments, especially where fire safety standards are a priority. Additionally, customisable jacket formulations allow buyers to tailor UV resistance, color coding, softness, or chemical resistance based on project needs.

Summary

Cable jacket materials vary widely, and selecting the right PVC, PE, or LSZH jacket ensures long-lasting, safe, and reliable performance for any project.