Are You Struggling to Understand What PVC Insulation Control Cable Really Is?

Many engineers and buyers often face confusion when selecting the right PVC insulation control cable. The problem usually arises from unclear specifications, inconsistent quality from inexperienced suppliers, or missing data on the conductor, insulation, and jacket materials. These issues can lead to system malfunction, signal instability, and unexpected maintenance costs. As a professional manufacturer, wholesaler, and long-term supplier of high-quality, customisable control cables, QRUNNING helps clients solve these challenges through transparent specifications, factory testing, and dependable export experience, ensuring that every project operates safely and efficiently.

A PVC insulation control cable is a low-voltage control cable designed for signal transmission and equipment operation. It uses copper conductors with a PVC insulation layer and protective jacket to ensure stability, durability, and safe operation in industrial and commercial environments.

To better understand how these cables work and where they are used, explore the following detailed sections that break down structure, benefits, and real-world applications.

Related products: PVC Insulation Control Cable – Qrunning is manufacturer of wires and cables in china

What is PVC Insulation Control Cable

A PVC insulation control cable is a specialised electrical cable designed to carry control signals, monitoring data, and low-voltage operational commands within industrial and commercial systems. The cable typically uses high-purity copper conductors to ensure stable electrical performance, while its insulation and jacket layers are manufactured from high-grade PVC compounds for safety and durability. As a trusted manufacturer and supplier, we produce customisable versions for various industries where reliable communication between equipment is essential.

Unlike power cables that carry high loads, control cables operate at lower voltages yet require high precision and protection. Their design aims to minimise electrical interference, reduce attenuation, and maintain performance even in complex control circuits. This makes them ideal for automation systems, PLC control loops, instrumentation networks, and centralized management panels used in factories and buildings.

The Structure and Composition of PVC Insulation Control Cable

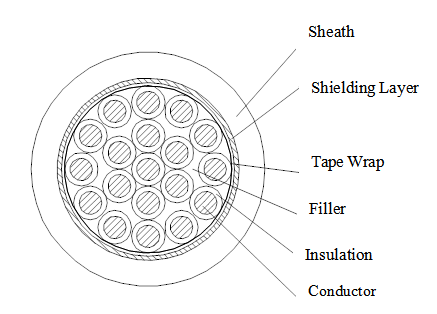

Understanding the internal structure of a PVC insulation control cable is vital for correct selection. The core consists of stranded or solid copper conductors, chosen based on flexibility, conductivity, and installation conditions. Next is the insulation, where the PVC compound provides dielectric strength, temperature resistance, and moisture protection. Depending on the application, colour-coded insulation helps technicians identify circuits easily during wiring and troubleshooting.

The outer jacket is another key component. It protects the insulated cores from mechanical pressure, abrasion, and mild chemicals. For industrial environments, the jacket may be strengthened or made flame-retardant. As a quality-driven manufacturer, QRUNNING ensures the layers are extruded uniformly, maintaining consistent thickness and long-term stability. For contractors and wholesalers who require tailored specifications, we also offer customisable jacketing options.

What are the Advantages

PVC insulation control cables offer several advantages that make them widely used across industries. Their PVC insulation delivers reliable dielectric strength while resisting moisture, oil, and standard abrasions. The copper conductor provides excellent electrical performance with minimal signal loss. These features combine to deliver long-term reliability and stable operation in control systems.

Cost-effectiveness is another major advantage. PVC compounds are economical yet effective, making these cables a strong option for contractors, engineering firms, and distributors seeking performance without excessive expense. As a high-capacity manufacturer and wholesaler, we streamline production to offer consistent quality, fast delivery, and customisable solutions suited for both small-scale and large-scale applications.

Applications of PVC-Insulated Control Cables

PVC-insulated control cables are commonly used across manufacturing plants, infrastructure projects, commercial buildings, and power control systems. They are essential for panel wiring, interconnection of electrical equipment, and transmitting low-voltage control commands in automated systems. Their flexibility and protective jacket design make them suitable for cable trays, ducts, or fixed installations.

Industries such as HVAC, machinery automation, water treatment, and energy distribution depend heavily on these cables due to their stability and cost efficiency. As a global supplier, QRUNNING provides customisable options to match installation environments, including core count variations, colour coding, and enhanced PVC formulations to support demanding operational conditions.

Summary

A PVC insulation control cable provides reliable signal transmission using quality conductors, PVC insulation, and a protective jacket. Manufacturers and suppliers like QRUNNING offer customisable solutions suitable for modern industrial control systems.