What is Solar Cable?

Solar cable refers to the specially designed electrical wire used to connect different components of a photovoltaic system. It plays a critical role in ensuring energy is transmitted safely and efficiently from the solar panels to the inverter and beyond. Manufactured to resist extreme environmental conditions, solar cables are essential for long-lasting and stable solar power systems.

Characteristics of Solar Cable

Solar cables are known for their high durability, UV resistance, and weatherproof insulation. These cables are typically rated for high voltage, extreme temperature ranges, and harsh outdoor environments. High-quality solar cable manufacturers ensure compliance with global standards, ensuring superior conductivity and long-term performance in solar power applications.

Applications of Solar Cables

Solar cables are used to connect solar panels, inverters, junction boxes, and batteries in photovoltaic systems. QRUNNING manufactures solar power cables suitable for residential, commercial, and industrial solar energy projects, offering OEM & ODM services for customized solutions.

Read on to explore the types, uses, and features of solar cables.

Types of Solar Cables

There are several types of solar cables used in photovoltaic installations, each tailored to specific needs and installation environments. The most commonly used include single-core and multi-core cables. Single-core solar cables are widely used for their simplicity and are ideal for interconnecting individual solar modules and inverters. Multi-core cables, on the other hand, integrate multiple conductors into a single cable, often used in more complex solar power systems where space and organization are critical.

Another essential type is the DC solar cable, specifically designed to handle direct current transmission from the solar panels to the inverter. These cables are insulated with materials such as XLPE or cross-linked polyethylene, offering enhanced resistance to thermal, mechanical, and UV exposure. AC solar cables are used on the output side of the inverter where the electricity becomes alternating current, and these typically follow different insulation standards.

QRUNNING, as a professional solar cable manufacturer and supplier, offers a wide range of solar cable options rated up to 1.5kV, suitable for harsh outdoor conditions. With our OEM and ODM support, clients can choose customized lengths, colors, and insulation materials to match specific project requirements, ensuring efficiency and safety in every solar installation.

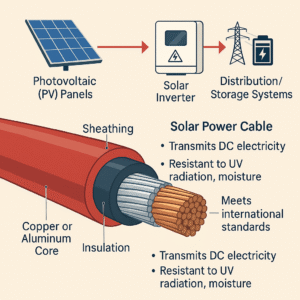

How Does Solar Cable Work?

Solar cables function by transmitting the electrical energy generated by photovoltaic (PV) panels to the solar inverter, and from there to the distribution systems or storage batteries. These cables are engineered to carry DC electricity from the solar modules, which is later converted into usable AC electricity by the inverter. Proper selection of solar cable is critical to minimize energy loss, voltage drop, and ensure safety

over long distances.

over long distances.

Solar power cables are constructed using high-conductivity copper or aluminum cores. The insulation and sheathing materials, usually XLPE or rubber-based compounds, offer resistance to UV radiation, ozone, moisture, oil, and extreme temperatures. This design ensures durability and performance under direct sunlight, rain, snow, and temperature fluctuations common in outdoor PV installations.

Moreover, solar cables must meet international safety and quality standards, such as TUV and IEC certifications. Leading solar cable suppliers like QRUNNING conduct rigorous quality control testing on every batch, ensuring consistent conductivity, flexibility, and resistance to environmental stress. By using our solar cables, clients can avoid common installation issues, system inefficiencies, or premature cable degradation.

Where Are Solar Cables Used?

Solar cables are primarily used in photovoltaic (PV) systems across a wide range of applications, from residential rooftops and commercial buildings to large-scale solar farms and off-grid installations. These cables connect solar panels to junction boxes, combiner boxes, charge controllers, inverters, and eventually to the electrical grid or storage systems. Their robust design allows them to withstand long-term outdoor exposure, making them suitable for both fixed installations and mobile setups such as RVs and solar-powered boats.

In industrial and utility-scale solar energy systems, cable runs can extend over hundreds of meters, requiring cables that maintain voltage stability and physical integrity over distance. QRUNNING’s high-quality solar power cables are engineered with this in mind, offering low resistance and high durability to meet demanding installation environments. Our factory is equipped with ten production lines and has over 30 years of experience as a trusted solar cable manufacturer and exporter to regions like Vietnam, Kenya, and Ethiopia.

As global demand for clean energy rises, more EPC contractors, solar project developers, and electrical equipment distributors are turning to reliable solar cable suppliers who provide competitive pricing, verified certification, and consistent lead times. QRUNNING meets all of these criteria with a proven track record in B2B wholesale and OEM/ODM services.

Related articles:Guide to selecting cables for different climates

What is the Difference Between Solar Wire and Cable?

While the terms “solar wire” and “solar cable” are often used interchangeably, there are key technical differences between the two. A solar wire typically refers to a single conductor, either solid or stranded, which may or may not be insulated. It is suitable for internal wiring within solar equipment or in environments where protection and bundling are not necessary.

Solar cable, on the other hand, refers to a complete cable assembly that includes one or more conductors, insulation, and often an outer sheath. Solar cables are designed for use in harsh environments and are generally required for outdoor solar installations. They offer superior protection against mechanical stress, UV radiation, moisture, and chemicals, making them ideal for connecting solar panels to other PV system components.

Additionally, solar power cables are typically rated for higher voltage and temperature ranges, and they adhere to more rigorous testing and certification standards such as TUV, IEC, or UL. QRUNNING, as a leading solar cable manufacturer, offers both solar wires and cables, with custom solutions to fit specific technical and regulatory requirements. When planning a solar installation, it’s critical to consult with a qualified solar cable supplier to ensure the right cable type is selected for the intended application.