What is the HV (High Voltage) Cable?

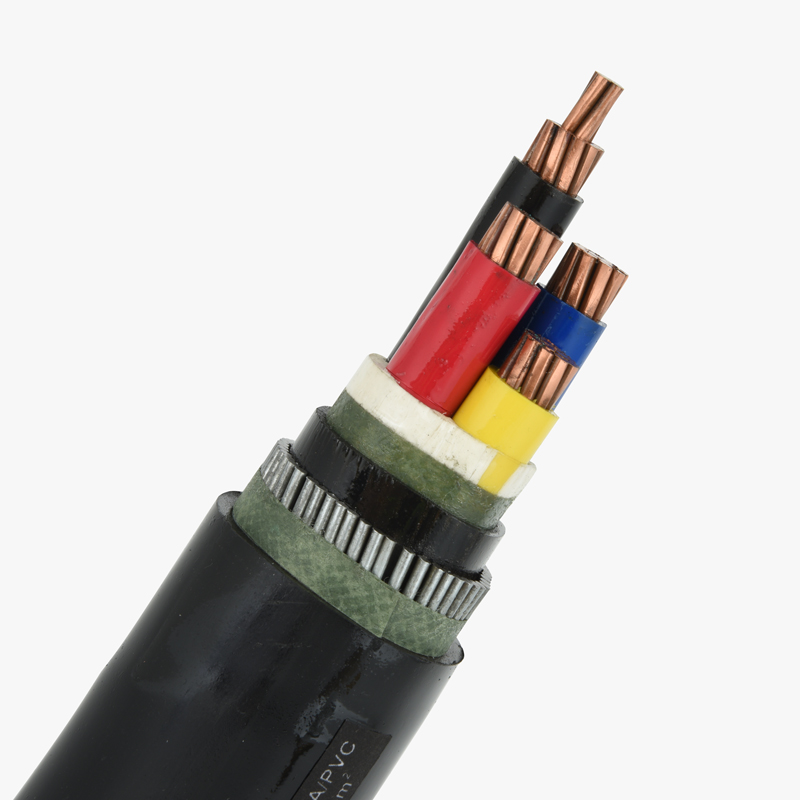

High Voltage (HV) cables are specifically designed to carry electricity at higher voltages, typically above 1 kV (kilovolt). These cables are integral to transmitting power over long distances, from power plants to distribution networks. In industries such as energy, transportation, and telecommunications, HV cables are crucial to the reliable and efficient delivery of electricity. High voltage cables come in various types, each suited for specific applications like underground cables, overhead cables, and submarine cables. The construction of HV cables involves multiple layers of insulation and shielding to ensure safe transmission, prevent leakage, and avoid electrical faults.

High voltage electric cables are typically used in power transmission systems to supply electricity over long distances, minimizing energy loss. HV cables are commonly made with materials like copper or aluminum for conductivity, and their insulation materials are chosen based on the environmental conditions they will face, such as polyethylene, XLPE, or rubber. For added protection, these cables may also include shields to guard against external damage, electromagnetic interference, and environmental conditions such as moisture, heat, or chemicals.

What is the MV (Medium Voltage) Cable?

Medium Voltage (MV) cables, as the name implies, are used for transmitting electrical power at medium voltages typically between 1 kV and 36 kV. These cables are most commonly found in power distribution networks, where they connect power substations to various distribution points. MV cables are crucial in the last stage of the electricity transmission process, delivering power to homes, factories, and commercial buildings. Their insulation materials vary, with XLPE being the most common due to its high dielectric strength, excellent thermal properties, and resistance to moisture and mechanical stress.

Unlike HV cables, MV cables are not designed for long-distance transmission but are used for localized power distribution. While HV cables require more robust construction to handle higher electrical loads, MV cables are still built with high-quality materials to prevent electrical faults and leakage. MV cables are used in various applications, including industrial plants, utilities, and in connecting to high voltage transformers to step down the voltage for further distribution.

What is the Difference Between HVDC and HVAC?

The difference between HVDC (High Voltage Direct Current) and HVAC (High Voltage Alternating Current) lies primarily in the type of electrical current each cable transmits. HVDC cables carry direct current (DC), while HVAC cables transmit alternating current (AC). The distinction has significant implications in terms of efficiency, distance, and application. HVDC systems are often used for long-distance power transmission and undersea cables because DC suffers less energy loss compared to AC. HVAC, on the other hand, is more commonly used for power distribution across shorter distances and for systems that rely on alternating current for power generation and consumption.

HVDC is ideal for efficient, long-distance transmission, such as intercontinental power lines, while HVAC is more suitable for local grid systems. One of the primary advantages of HVDC over HVAC is the reduced energy loss during transmission, especially when transporting power across large distances. HVAC systems, while efficient for shorter distances, experience more energy losses due to the skin effect and line resistance. High voltage DC cables are also essential for connecting grids that operate on different frequencies or where a direct connection is required between two regions with different AC grids.

What is the Function of Medium Voltage Cable?

The primary function of medium voltage cables is to transmit electrical power from the substation to local distribution points. These cables typically range from 1 kV to 36 kV in voltage and serve as a bridge between high voltage transmission lines and low voltage distribution networks. MV cables are crucial in ensuring the safe and reliable delivery of electricity over shorter distances within towns, industrial zones, or residential areas.

MV cables are widely used in various applications like power distribution in buildings, street lighting, and industrial machinery. They are often buried underground to protect them from external factors such as weather and physical damage. MV cables are designed with insulating materials that prevent electric shocks and ensure the safe transfer of power. In some cases, they are also armored to resist mechanical stress and provide additional safety against accidental impacts or abrasions.

What is the Function of High Voltage Cable?

High voltage cables have a primary function of transmitting electrical power over long distances with minimal loss. These cables carry voltages typically above 36 kV and are used to connect power plants, substations, and long-distance transmission lines. HV cables are essential in the generation and transportation of electricity to be distributed across cities, industries, and rural areas. Due to their high voltage capacity, these cables are engineered with superior insulation materials and protective coatings to withstand the immense pressure of electrical loads.

Another crucial function of high voltage cables is to facilitate the stable operation of power grids by minimizing energy loss during transmission. HV cables also play a key role in the development of renewable energy projects, where long-distance transmission is needed to connect renewable energy generation sites (like offshore wind farms or solar farms) to the main grid. These cables ensure that power is delivered efficiently and reliably from renewable sources to end consumers.

Summary

HV and MV cables play distinct yet crucial roles in the electrical power grid. HV cables are used for long-distance transmission of electricity at high voltages, while MV cables are used for distribution within local networks. Choosing the right cables from trusted high voltage cable manufacturers ensures safe, efficient, and reliable power delivery for all applications.

About Qrunning

Qrunning is a professional engaged in wire and cable research & development, production, sales and service enterprises.The main products are three series of wires and cables of 500kV and below.Qrunning started in 1990 and entered the top 50 of China’s cable industry in 2015.Dedicated high-voltage cable production base established in 2011.