What is the Role of Cable Armoring?

As a professional electrical cable wholesaler, manufacturer, and supplier, you might often wonder: why do certain power cables include an extra metallic layer called “armor”? Many construction and power engineering companies face costly damage and safety risks when cables are crushed, bitten by rodents, or exposed to harsh installation environments. These issues can result in short circuits, downtime, and replacement expenses. The solution lies in using armored cables, specifically steel tape armor or steel wire armor designs. With over 30 years of experience, QRUNNING provides customizable armored cables that combine superior protection, reliable quality, and flexible OEM/ODM service for global clients across Africa and Asia.

Armored cables use protective metal layers, such as steel tape or steel wire armor, to enhance mechanical strength, prevent damage, and ensure long-term safety in harsh installation environments.

Let’s dive deeper into what makes armored electrical cables essential for modern power systems and how to choose the right type for your project needs.

What Exactly is an Armored Electrical Cable

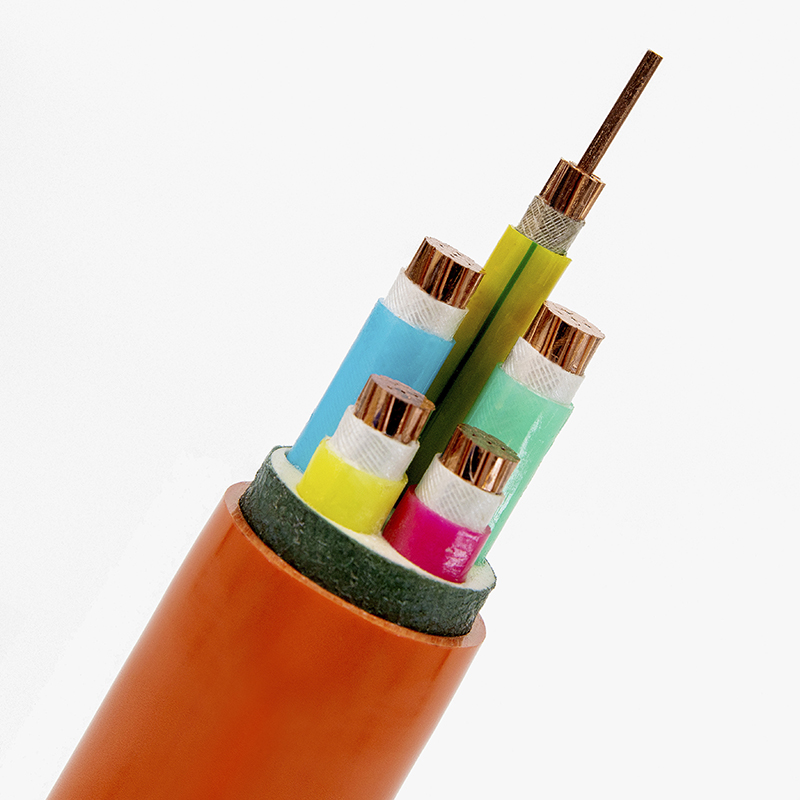

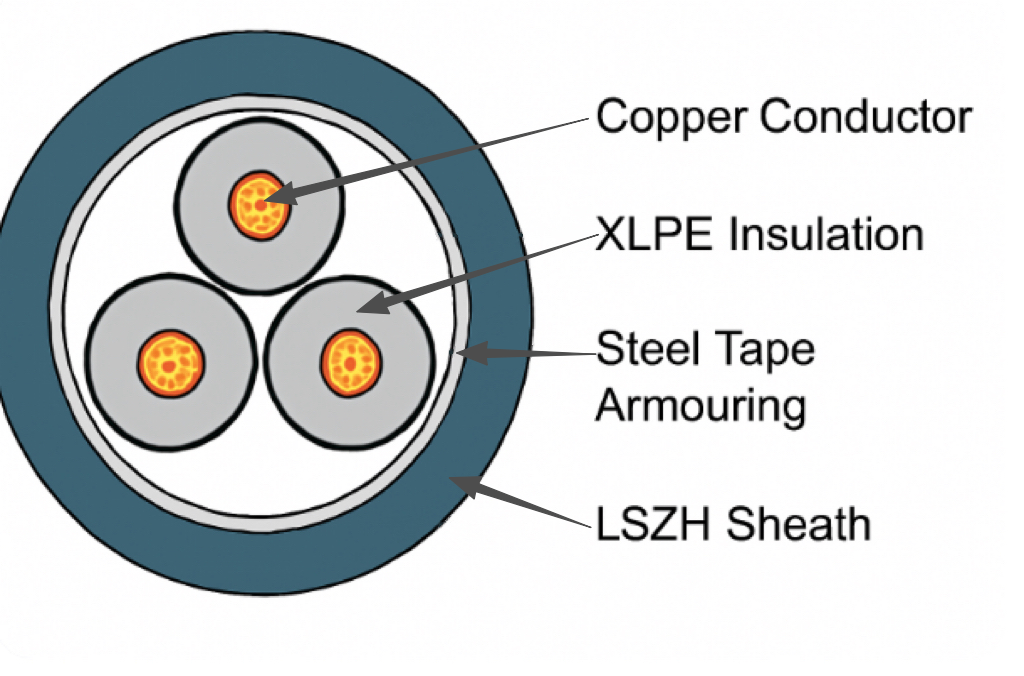

An armored electrical cable is a type of power or control cable that includes a metallic protective layer between the cable’s insulation and outer sheath. This layer—often made from steel tape or steel wire—acts as a mechanical barrier to protect internal conductors from physical impact, compression, moisture, or chemical corrosion. Unlike standard cables, armored cables are designed for underground installation, industrial applications, and outdoor environments, where mechanical stress or environmental hazards are common.

The armor not only enhances durability but also provides electromagnetic shielding, reducing interference from nearby power lines or equipment. As a leading cable manufacturer, QRUNNING ensures that each armored cable meets international safety standards such as IEC and BS, providing clients with dependable products that withstand challenging conditions. With customizable armor types and sizes, clients can select the most suitable cable design for their voltage levels and application environments.

Related products:Armored Cable – Qrunning Wire And Cable

What is the Role of Cable Armor

The primary role of cable armor is to provide mechanical protection and environmental resistance. During installation, cables may be dragged over rough surfaces, buried in soil, or exposed to rodents and moisture. Without armor, the insulation or conductors could be damaged, leading to electrical faults or system failure. Steel tape armor (STA) and steel wire armor (SWA) each serve specific roles based on environmental and structural requirements.

Steel Tape Armor (STA)

Steel tape armor is a thin, overlapping strip of galvanized steel applied around the cable core. It provides excellent protection against compression and impact, making it ideal for indoor installations or underground environments where tensile strength is less critical. STA armored cables are commonly used in power distribution networks, industrial control systems, and building wiring projects where cost-effective mechanical protection is essential.

Related products:Steel Tape Armored (STA) Cable – Qrunning Wire And Cable

Steel Wire Armor (SWA)

Steel wire armor uses multiple round steel wires braided around the cable core, offering superior tensile strength and flexibility. This type is often used in outdoor installations, tunnels, and vertical applications, where the cable must endure pulling forces and vibration. In addition to physical protection, SWA also enhances electrical grounding capability, further improving safety performance. As a professional cable supplier, QRUNNING provides both STA and SWA armored cables that balance mechanical performance, corrosion resistance, and price competitiveness.

Related products:Steel Wire Armored (SWA) Cable – Qrunning Wire And Cable

Classification of Armored Control Cables

Armored control cables can be classified by their armor type, application environment, and voltage rating. The most common categories include:

1. By Armor Type

– Steel Tape Armored Control Cable (STA): Ideal for fixed installations, offering cost-effective protection against external mechanical impact.

– Steel Wire Armored Control Cable (SWA): Designed for higher mechanical stress and tensile load applications, suitable for vertical or outdoor settings.

2. By Application

– Indoor Control Cables: Used in automation systems, machinery, and power distribution control panels.

– Outdoor and Underground Control Cables: Equipped with waterproofing and corrosion-resistant features for long-term reliability in harsh environments.

3. By Voltage Level

– Low Voltage Armored Cables (Below 1kV): Commonly used in control and signal circuits.

– Medium and High Voltage Armored Cables (Up to 500kV): Designed for power transmission lines and grid projects requiring high performance and safety margins.

QRUNNING offers customizable armored control cables based on specific engineering requirements, ensuring optimal balance between durability, safety, and cost efficiency. All products undergo strict quality testing and certification to guarantee compliance with international standards.

Summary

Cable armor plays a crucial role in protecting electrical systems from mechanical and environmental damage. Choosing the right armored cable, whether steel tape or steel wire armor, ensures long-term reliability and safety in every project.