When to use armored cable?

Armoured cables are essential in situations where safety, durability, and protection from external factors

are needed. These cables, often used in industrial and commercial settings, are designed to withstand harsh conditions, offering enhanced protection for electrical wiring. The inclusion of a protective metal sheath makes them ideal for areas where cables are vulnerable to mechanical damage, moisture, or corrosive environments.

Where is armoured cable used?

Armoured cables are typically used in industrial settings, underground installations, and areas with high-risk exposure to physical damage. They’re also ideal for outdoor applications, including construction sites, mining, and power stations, where they need to withstand rough handling, impact, and environmental stress.

Read more:https://www.qrunningcable.com/industry/construction-cableswires/

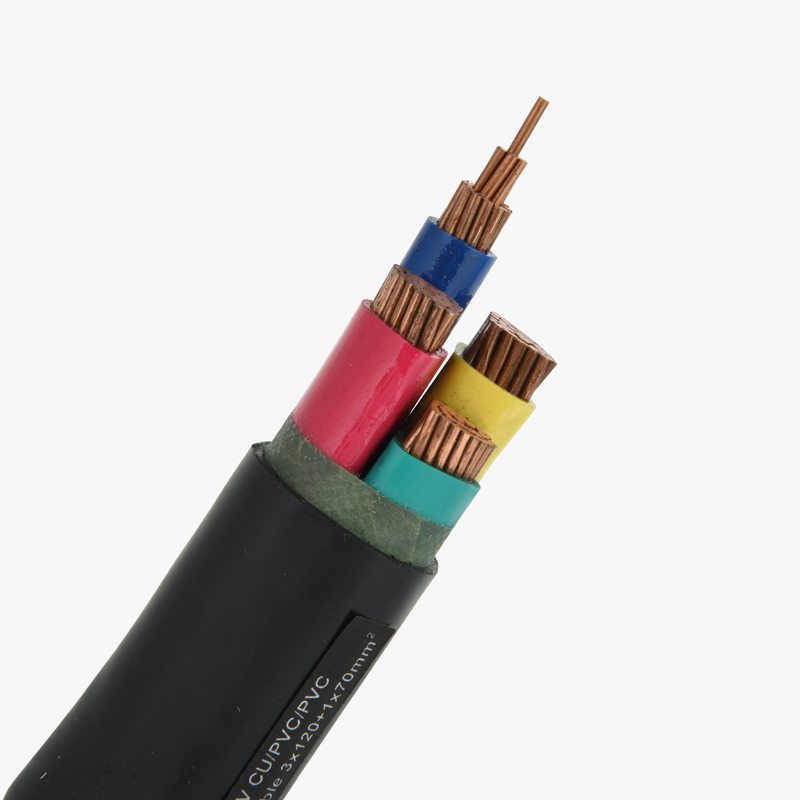

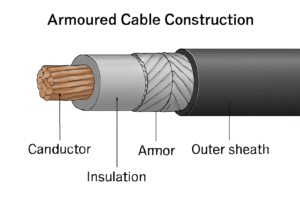

Armoured cable construction

Armoured cable construction consists of a combination of inner and outer layers that ensure the wire’

s protection. These cables usually include a core made of copper or aluminum for electrical conduction, surrounded by insulation, a protective layer of metal armor, and an outer sheath for added protection. Manufacturers, like those at Keystone Cable, offer a range of armoured cable products suited for various purposes.

Continue reading to learn more about the various aspects of armoured cables and their use in specific situations.

What is the difference between armoured cable and MC cable?

The primary difference between armoured cable and MC (Metal Clad) cable lies in the construction and level of protection offered. Armoured cables feature a thick metal sheath around the conductors, often made from steel or aluminum, designed to provide resistance against physical damage. On the other hand, MC cables also feature a metal jacket but may not be as heavy-duty as armoured cables, and some types of MC cables use aluminum, which offers less physical protection. Armoured cables are generally preferred in environments with a higher risk of mechanical impact, while MC cables may be suitable for less hazardous installations. Suppliers and manufacturers may recommend one type over the other based on the specific needs of the installation, environment, and cable’s durability requirements.

When is armoured cable required?

Armoured cable is required when there is a need for additional protection from physical damage, mechanical stress, or environmental hazards. Typically, it is used in industrial, outdoor, and underground electrical installations where the cable could be subjected to conditions like impact, vibration, moisture, or corrosive substances. For example, when installing cables in areas with heavy machinery or in locations exposed to weather elements, armoured cables ensure long-lasting durability and protection. Many manufacturers supply these cables in various configurations to meet the different safety standards required for these installations.

Read more:https://www.qrunningcable.com/sta-vs-swa-which-armoured-cable-type-should-you-choose/

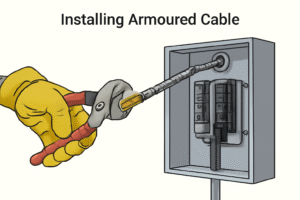

How to install armoured cable?

Installing armoured cable requires careful handling to ensure the protection of both the cable and the installer. To start, ensure the power is off before starting the installation. Use suitable tools for cutting and stripping the cable’s outer sheath. Once the cable is cut to the desired length, make sure to carefully connect it to electrical panels or junction boxes. The metal armoring should be properly grounded to avoid electrical hazards. For underground installations, ensure the cable is buried at the correct depth to avoid external interference. Proper installation ensures both the safety of the electrical system and the longevity of the armoured cable itself.

How to ground armoured cable?

Grounding armoured cable is essential for electrical safety and preventing electrical shocks. The outer metal armoring of the cable acts as a grounding conductor and should be connected to the ground of the electrical system. Typically, grounding is done by attaching a grounding clamp or connecting the armour to a grounded junction box. If the cable is run underground or in a hazardous location, the armouring must be bonded to the electrical panel to ensure that any fault currents are safely directed away. It’s important to follow local electrical codes and manufacturer guidelines when grounding armoured cable to ensure a safe and reliable installation.

Why use armoured cable?

Armoured cable offers several key advantages that make it the preferred choice in many industrial, commercial, and residential installations. The primary reason to use armoured cable is its durability and resistance to physical damage. Whether installed underground, in areas with heavy machinery, or exposed to harsh environmental conditions, armoured cables provide superior protection for electrical conductors. Furthermore, they are designed to minimize the risk of electrical faults caused by accidental damage. Manufacturers also offer armoured cables with specific designs for added flexibility and strength, making them suitable for a variety of applications, including high-stress environments. Additionally, their robust construction ensures a longer lifespan and enhanced safety for electrical systems.