What are PVC-insulated cables?

PVC-insulated cables are electrical wires coated with polyvinyl chloride (PVC), a durable plastic material used to insulate and protect conductors. These cables are designed to prevent electrical leakage, short circuits, and environmental damage. Known for their flexibility and resistance to heat and chemicals, PVC insulated wire is widely used in residential, commercial, and industrial applications. This versatile insulation type forms the backbone of many cable products offered by reliable manufacturers and suppliers.

The Advantages of PVC

PVC insulation offers excellent electrical and mechanical properties, including flame retardance, chemical resistance, and affordability. It is also lightweight and flexible, which makes installation easier across various settings. Manufacturers choose PVC for its consistent performance and ease of processing, while suppliers appreciate its long shelf life and low maintenance. These characteristics make PVC wire insulation a go-to choice for diverse electrical applications.

Wide-Ranging Use

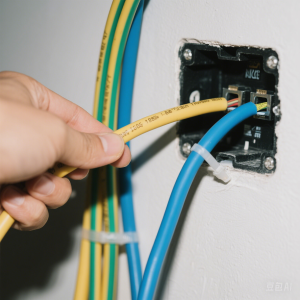

PVC-insulated wires are used in low-voltage power distribution, home wiring,

industrial control systems, and automotive wiring. They are favored by cable manufacturers and suppliers for their adaptability and cost-effectiveness. QRUNNING, a leading manufacturer in China, offers high-quality PVC insulated wire designed for developing markets like Vietnam, Ethiopia, and Kenya. Whether for indoor or outdoor applications, PVC wire insulation remains a reliable and economical solution for a wide range of electrical needs.

Let’s explore in-depth why PVC insulation is so effective and how it compares to other materials.

Is PVC a thermal conductor or insulator?

PVC is classified as a thermal and electrical insulator, which makes it an ideal material for cable insulation. It does not conduct heat or electricity, thereby protecting the cable’s conductive core from external temperature changes and minimizing the risk of electrical accidents. The molecular structure of PVC prevents free electrons from moving easily, reducing its conductivity. Manufacturers prefer PVC insulation because it offers stable performance across a wide temperature range, typically from -15°C to 70°C. Suppliers distribute PVC insulated wire globally due to its ability to withstand high electrical stress and environmental wear without losing its insulative properties. In environments where overheating, short circuits, or external interference is a concern, PVC wire insulation delivers safety and reliability with cost efficiency.

PVC vs. XLPE

When comparing PVC insulation with XLPE (cross-linked polyethylene), several differences become evident. While both materials offer strong insulative properties, PVC is more flexible and cost-effective, whereas XLPE provides better thermal resistance and can operate at higher temperatures, typically up to 90°C or more. PVC insulated wire is often selected for low- to medium-voltage applications, including household wiring and indoor circuits, while XLPE is suited for higher voltage installations and environments with extreme temperatures. Manufacturers might choose XLPE for heavy-duty industrial use, but PVC remains the preferred option among suppliers for standard wiring projects due to its lower cost, ease of processing, and fire-retardant features. Ultimately, the decision between PVC and XLPE depends on the specific requirements of the project, including budget, operating temperature, and voltage demands.

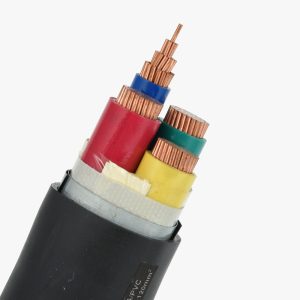

How are PVC cables made?

The manufacturing process of PVC-insulated cables involves several precise stages.

First, high-conductivity copper or aluminum conductors are drawn and stranded to the required size and shape. Next, these conductors pass through an extrusion machine, where melted PVC is applied as a uniform insulating layer. The PVC compound, formulated with stabilizers and flame retardants, ensures the cable meets electrical and mechanical standards. After extrusion, the cable is cooled, tested for insulation resistance, and then cut and coiled for packaging. Trusted manufacturers like QRUNNING utilize automated production lines to ensure consistency, quality, and high output. As a result, suppliers receive reliable PVC insulated wire that meets international safety certifications. OEM and ODM services further allow customization based on voltage rating, color coding, and insulation thickness, giving distributors the flexibility to serve a variety of market needs efficiently.