What is XLPE Insulation? XLPE (cross-linked polyethylene) insulation is a high-performance polymer used in power and electrical cables for enhanced thermal, chemical, and mechanical durability.

Technical Specifications – Our XLPE insulation meets IEC and IEEE standards, offers up to 90 °C continuous operating temperature, excellent dielectric strength, and OEM & OEM service advantages with in-house production capacity of 200M m. This makes us a competitive electrical cable XLPE supplier.

XLPE Applications – Cable XLPE is ideal for medium‑ and high‑voltage power distribution, industrial wiring, solar and wind farms, and underground transmission lines, used by manufacturers and contractors worldwide.

Continue reading to explore key questions about XLPE wire insulation.

What is XLPE cable used for?

XLPE cable is utilized across a wide range of electrical and power distribution systems where reliability and durability are critical. As a leading cable XLPE manufacturer, our products serve large-scale power grid companies, power engineering contractors, and industrial facilities in developing markets. The cross‑linked structure provides high thermal resistance, allowing continuous operation up to 90 °C and short-term tolerance to 130 °C. This makes electrical cable XLPE ideal for medium‑voltage (1 kV to 33 kV) and high‑voltage (66 kV, 110 kV, up to 500 kV) applications. Common uses include underground and aerial power transmission, solar and wind farm cabling, industrial plant wiring, and utilities. Compared to traditional PVC, XLPE cable offers better chemical resistance, longevity, and lower thermal expansion, reducing failure risks. Our customers appreciate the quality and certifications—ISO, IEC—from our factory with 10 production lines, ensuring steady supply and dependable logistics. This combination of quality, certification, and competitive pricing makes us a trusted supplier in the XLPE wire market.

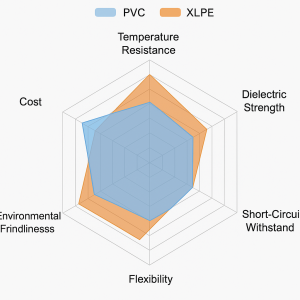

What is the difference between PVC and XLPE insulation?

PVC and XLPE are both used for cable insulation, but they differ significantly in performance and application. PVC (polyvinyl chloride) is less costly and flexible, making it suitable for low‑voltage wiring (up to 1 kV) in household and control cables. However, electrical cable XLPE offers superior heat resistance, mechanical strength, and dielectric performance. XLPE operates reliably at continuous temperatures of 90 °C and peak temperatures of 130 °

C, while PVC typically maxes out around 70 °C. XLPE’s cross‑linked molecular structure delivers enhanced resistance to chemical corrosion, moisture, abrasion, and thermal aging. Conversely, PVC may degrade faster under h

igh temperature or load conditions, increasing failure risk. In addition, XLPE insulation contributes to lower dielectric losses and higher current‑carrying capacity. Manufacturers, suppliers, and contractors often choose XLPE over PVC for medium- and high-voltage projects, bidding for infrastructure tenders or large-scale installations. As a

specialized manufacturer of cable XLPE, we deliver high-quality, certified XLPE wire insulation at competitive wholesale prices, with full technical support and OEM/ODM services.

What does XLPE stand for?

XLPE stands for cross‑linked polyethylene, a type of insulating polymer created by chemically cross-linking polyethylene chains. This cross-linking process—achieved via peroxide, silane, or electron beam methods—alters the molecular structure of polyethylene to create a thermoset material with greater strength and temperature resilience. The result is XLPE insulation that resists deformation, heat, chemicals, and aging. Unlike standard PE, which melts when reheated, XLPE maintains its shape under thermal stress, making it ideal for electrical cable XLPE applications. As a major manufacturer and supplier, our XLPE wire insulation is processed in-house across 10 production lines, ensuring consistency and compliance with IEC 60840, IEC 62067, IEEE, and other standards. Our OEM & ODM flexibility allows customization—colored insulation, semi-conductive layers, or fire‑resistant additives—to meet various project specifications. Offering fast lead times, quality control, and logistics tailored for export markets like Kenya, Ethiopia, and Vietnam, we are a preferred cable XLPE factory.

What is XLPE cable insulation?

XLPE cable insulation refers to the cross‑linked polyethylene layer that surrounds the conductor in power and electrical cables. This insulation has key roles: ensuring electrical isolation, maintaining dielectric strength, and protecting the conductor from external damage. The thermoset XLPE material supports long-term performance under mechanical stress, moisture ingress, and corrosive environments—ideal for medium- and high-voltage applications. As an experienced electrical cable XLPE manufacturer, we integrate this insulation into cable production with precise thickness control, extrusion accuracy, and cross-link degree. Our factory’s quality management involves sampling, testing for dielectric strength, thermal endurance, and partial discharge. Additionally, XLPE insulation’s low dielectric loss reduces energy waste and operational costs. Whether embedded underground, run through ducts, or installed on pylons, XLPE cable insulation from our factory excels in both reliability and durability. Supplying global markets with certified, quality-inspected cable XLPE, we support OEM/ODM packaging and logistics, facilitating hassle-free deliveries to distributors, contractors, and utilities.

What is XLPE wire insulation?

XLPE wire insulation specifically refers to the cross-linked polyethylene covering used on individual wires typically found in building wiring, control cables, or industrial harnesses. As a manufacturer and supplier of electrical cable XLPE, our XLPE wire meets stringent insulation thickness and voltage ratings suitable for low- and medium-voltage levels. This insulation is resistant to heat, chemicals, moisture, and physical damage, making it ideal for demanding environments. Benefits include improved current-carrying capacity thanks to lower dielectric losses, longer service life, and enhanced fire resistance. We offer OEM/ODM customization—color coding, double or triple layers, and flame retardant additives—to match project specifications. Quality-controlled with precise extrusion and curing processes, our XLPE wire insulation is certified under IEC and UL standards. Distributed through our export network to developing countries like Angola, Sudan, and Uzbekistan, our cable XLPE products enable smooth bidding and project execution.

Summary: XLPE insulation offers high performance, reliability, and versatility for demanding cable applications.