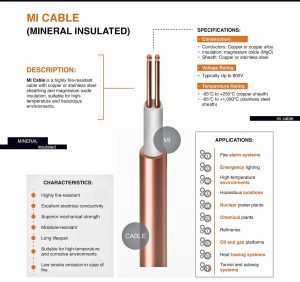

Five Major Application Scenarios of MI Cables

Mineral Insulated (MI) cables are widely used in critical environments requiring high reliability, fire resistance, and safety. Their five major applications include: 1) Emergency power systems in hospitals and data centers; 2) Fire alarm systems and evacuation lighting in high-rise buildings; 3) Power supply for oil & gas facilities, chemical plants, and nuclear stations; 4) Tunnels and metro rail infrastructure, where fireproofing is essential; 5) Military installations and offshore platforms where extreme environmental durability is required. MI cables’ superior fireproof and corrosion-resistant properties make them ideal for installations with high safety standards and exposure to hazardous environments.

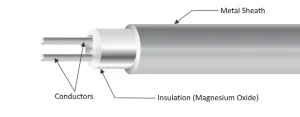

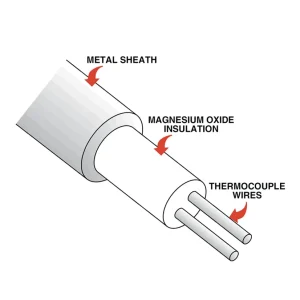

Basic Structure and Composition of MI Cables

MI cables consist of copper conductors encased in a compacted magnesium oxide (MgO) insulation, all enclosed within a seamless copper sheath. This inorganic structure allows for unmatched fire resistance, high-temperature tolerance, and mechanical protection. The absence of organic materials eliminates combustion risks, making MI cables uniquely suited for extreme conditions.

Core Advantages of Fire Resistance and Fireproofing, Compared to Other Fireproof Cables

MI cables are rated to withstand over 950°C for more than 3 hours (per IEC 60331 standards), outperforming traditional fire-resistant cables with organic insulation. In comparative tests:

| Feature | MI Cable | XLPE Fire-Resistant Cable | Silicone-Insulated Cable |

|---|---|---|---|

| Max Temp Resistance | >950°C | 750°C | 650°C |

| Flame Spread | Zero | Minimal | Moderate |

| Smoke Emission | None | Low | Medium |

| Duration of Fire Withstand | >180 mins | 90-120 mins | Up to 60 mins |

As visualized in the table, MI cables deliver maximum safety performance, making them indispensable for mission-critical installations where failure is not an option.

Installation Process and Special Requirements

MI cable installation demands precision: The bending radius must be at least 6 times the cable diameter. Cable ends must be carefully sealed with waterproof brass or stainless-steel glands to prevent moisture intrusion. Special terminal joints should be filled with fireproof sealant to ensure long-term durability. All exposed sections should be handled with care to maintain the integrity of the copper sheath and insulation.

Cost-Benefit Analysis of MI Cables

While MI cables are more expensive upfront—typically 2.5 to 3 times the price of XLPE fire-rated cables—they offer longer service life (>30 years), zero maintenance, and higher safety margins. For example, in a 10,000-meter project, total lifecycle cost including maintenance and fire damage risk could be 35% lower using MI cables due to reduced downtime and replacement costs. This makes them economically advantageous for high-risk or critical systems.

Summary and Recommendations

MI cables provide unmatched fireproof performance, safety, and durability. We recommend them for high-risk, mission-critical environments where long-term reliability justifies the investment.