In 2025, Qrunning Cable made outstanding achievements in technological innovation, securing a total of 17 patent grants throughout the year. Among these, there were 2 invention patents and 15 utility model patents, with the annual number of authorized patents hitting a new historical high. These achievements not only fully demonstrate the company’s profound R&D accumulation and technical strength but also further consolidate its position as a technological leader in the wire and cable manufacturing industry.

The two invention patents obtained this year represent breakthrough progress in key production process technologies:

A High Air-Concentrating Wire-Drawing Water Blower addresses the issue of low drying efficiency in traditional wire-drawing processes. Through an innovative air flow design, it significantly improves the surface drying effect of wires, reduces energy consumption, and enhances production efficiency. This technology resolves the long-standing industry bottleneck in single-wire surface cleaning during the wire-drawing process, providing a reliable guarantee for high-quality wire production.

A Method for Adjusting the Hot Melt Adhesive Spraying Range of Flat Aluminum Sheaths revolutionizes the cable sheath production process. By precisely controlling the spraying range and thickness of hot melt adhesive, it improves the uniformity and adhesion of the cable’s anti-corrosion layer, enhancing the product’s reliability and durability in complex environments. This method not only extends the service life of equipment but also avoids material waste and improves product quality, delivering significant economic and environmental benefits.

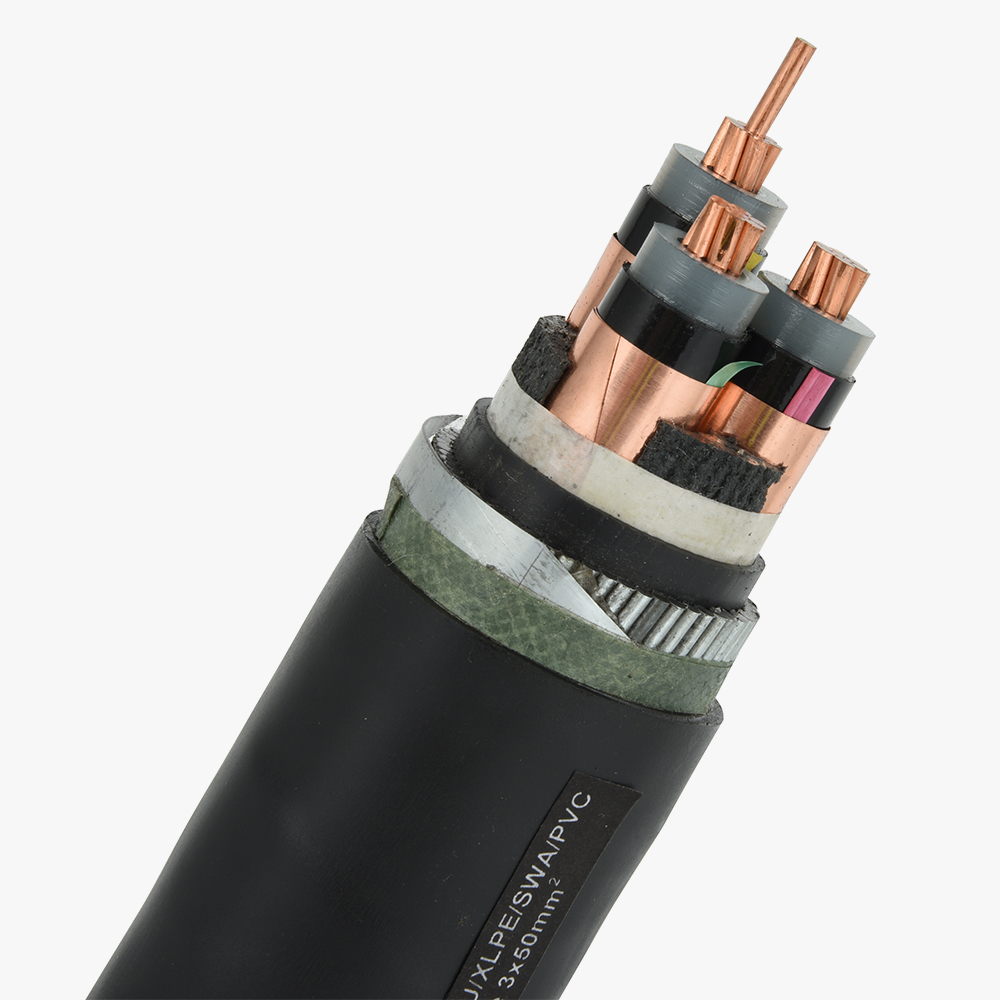

In addition to the two invention patents, the company also secured 15 utility model patents, including A Robot Drag Chain Cable, A Water-Resistant and Rodent-Termite Proof Photovoltaic Cable, An Anti-Theft Grounding Return Power Cable, and A Medium-Voltage Three-Core Cable with Water-Resistant and Withstand Voltage Detection Functions. These patents cover various aspects such as cable product innovation, production equipment improvement, and process optimization, playing a positive role in enriching the company’s product portfolio, improving quality, reducing costs, increasing efficiency, and enhancing overall competitiveness. As a high-tech enterprise specialized in the R&D and manufacturing of wires and cables, Qrunning Cable has been recognized as a National-level “Little Giant” Enterprise (Specialized, Refined, Unique, and Innovative) and a National Intellectual Property Advantage Enterprise.

In recent years, the company has continuously increased R&D investment, accelerated the construction of R&D platforms, and promoted product iteration and upgrading. In 2025, the company’s Central Laboratory obtained CNAS accreditation. The product New High-Strength, Tough and Heat-Resistant Aluminum Conductor, which was included in the Beilun District Key Core Technology Research Project, successfully completed the optimization design of material composition, as well as research on the microstructure, heat resistance, electrical conductivity, and mechanical properties of aluminum conductors, passing the mid-term acceptance inspection. A series of new product R&D achievements have continued to emerge, including 500kV extra-high voltage cables, charging gun cables, marine engineering cables, and new photovoltaic cables certified by TÜV Rheinland. Through a sound innovation mechanism and a comprehensive intellectual property management system, the company provides a solid guarantee for the efficient advancement of R&D work and the transformation of achievements, continuously enhancing its overall strength in the field of intellectual property.

As of December 31, 2025, the company holds a total of 71 valid patents, including 16 invention patents. This marks the solid results achieved by the company’s long-term adherence to the technological innovation strategy. Looking ahead, we will keep pace with cutting-edge industry technologies, focus on the pain points of market demand, base ourselves on improving quality, reducing costs and increasing efficiency, and take “Green, Intelligent, High-End” as the development direction. We will continue to deepen technological innovation, consolidate the foundation of quality, continuously enhance the company’s comprehensive competitiveness, and actively promote industrial upgrading.